BY ORDER OF THE SECRETARY

OF THE AIR FORCE

AIR FORCE MANUAL 24-306

30 JULY 2020

Transportation

OPERATION OF AIR FORCE

GOVERNMENT MOTOR VEHICLES

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY

ACCESSIBILITY: Publications and forms are available on the e-Publishing website at

www.e-Publishing.af.mil for downloading or ordering

RELEASABILITY: There are no releasability restrictions on this publication

OPR: AF/A4LR

Supersedes: AFMAN 24-306,

30 April 2020

Certified by: AF/A4L

(Brig Gen Linda S. Hurry)

Pages: 151

This publication implements Air Force Policy Directive (AFPD) 24-3, Management, Operation

and Use of Transportation Vehicles, and supports Air Force Instruction (AFI) 24-301, Ground

Transportation, for the use of Air Force (owned, rented or leased) government motor vehicles

(GMVs). It is a guide to everyday operations, as well as driving under difficult conditions. For

the purposes of this document, GMV refers to owned, rented, or leased tactical or non-tactical

vehicles operated on or off-highway. When more information is needed for a specific vehicle,

check the Manufacturer’s Operators Manual, Technical Order (TO), or Qualification Training

Package (QTP) written for that vehicle. It applies to all organizations and personnel, including

Air Force civilian employees and members of the Civil Air Patrol, when conducting missions for

the Air Force as the official Air Force Auxiliary, that use GMVs in any way, including the Air

Force Reserve (AFR), and Air National Guard (ANG), except where noted otherwise. Send

comments and suggested improvements on AF Form 847, Recommendation for Change of

Publication through Air Force Installation and Mission Support Center (AFIMSC) functional

managers to United States Air Force, Directorate of Logistics (USAF/A4LR), Deputy Chief of

Staff (DCS)/Logistics, Engineering & Force Protection, 1030 Air Force Pentagon, Washington

DC 20330-1030. This publication may be supplemented at any level, but all Supplements must

be routed to the OPR of this publication for coordination prior to certification and approval.

MAJCOM supplements must also be routed to USAF/A4LR prior to certification and approval

for implementation. The authorities to waive wing/unit level requirements in this publication are

identified with a Tier (“T-0, T-1, T-2, T-3”) number following the compliance statement. See

AFI 33-360, Publications and Forms Management, for a description of the authorities associated

with the Tier numbers. Submit requests for waivers through the chain of command to the

appropriate Tier waiver approval authority, or alternately, to the requestor’s commander for non-

2 AFMAN24-306 30 JULY 2020

tiered compliance items. Ensure all records created as a result of processes prescribed in this

publication are maintained in accordance with AFMAN 33-363, Management of Records, and

disposed of in accordance with the Air Force Records Disposition Schedule located in the Air

Force Records Information Management System.

SUMMARY OF CHANGES

This document has been substantially revised and must be completely reviewed. Significant

changes include the reduction of duplicative guidance, choosing instead to direct the reader to

the most appropriate guidance. There was also a significant reduction in acronyms and

abbreviations throughout the manual. Where appropriate, waiver authority has been lowered and

directive statements removed to afford greater installation-level latitude in application of ground

transportation services. Previously consisting of 16 chapters; the rewritten manual now consists

of 14 chapters. Major changes include the removal of general driving information and operation

of motor vehicles on military air fields.

AFI 36-2651, Air Force Training Program is now obsolete and has been updated to reflect AFI

36-2670, Total Force Development. Added to the definition of Direct Mission Support to

include Aircrew. Removed paragraph 1.7.4 (misuse reporting) to deconflict with AFI 24-301.

Updated UDI definition to deconflict with AFI 24-301 Para 3.16.3. Updated verbiage for

maintaining log of misuse cases. They are to be kept on file for three years IAW 24-301.

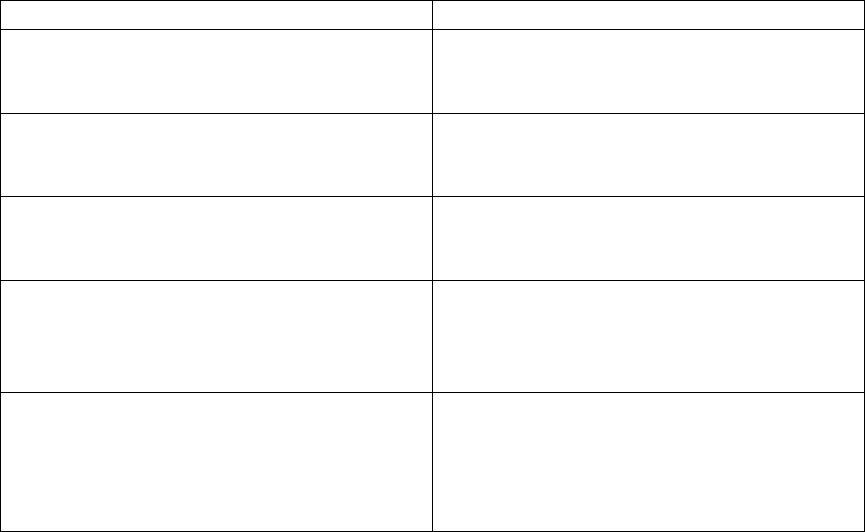

Chapter 1—ROLES AND RESPONSIBILITIES 15

Section 1A—Introduction 15

1.1. Introduction. ............................................................................................................. 15

Section 1B—Roles and Responsibilities 15

1.2. USAF/A4LR - Headquarters USAF Logistics Readiness Division ......................... 15

1.3. AFIMSC, NGB and AFRC ...................................................................................... 15

1.4. Installation Commanders and Directors (or equivalent). ......................................... 15

1.5. Logistics Readiness Squadron Commanders and Directors (or equivalent) ............ 16

1.6. Unit Commanders .................................................................................................... 16

1.7. LRS - Ground Transportation .................................................................................. 16

1.8. Vehicle Control Officials ......................................................................................... 17

Chapter 2—OFFICIAL USE OF GOVERNMENT MOTOR VEHICLES 18

Section 2A—Official Use Requirements 18

2.1. Official Use of GMVs. ............................................................................................. 18

AFMAN24-306 30 JULY 2020 3

Section 2B—General Use Responsibilities 18

2.2. General Use Responsibilities. .................................................................................. 18

2.3. Making Official Use Determinations. ...................................................................... 19

2.4. Priority of Transportation Services. ......................................................................... 19

2.5. Vehicle Misuse Reporting. ...................................................................................... 19

2.6. Penalties for Misuse of DoD Motor Vehicles. ......................................................... 20

Section 2C—Authorized Uses of GMVs for Temporary Duty Support 20

2.7. Temporary Duty. ...................................................................................................... 20

Section 2D—Standard Authorized Uses of GMVs for Permanent Party Mission Support 20

2.8. Permanent Party. ...................................................................................................... 20

2.9. Event Participation. .................................................................................................. 21

Section 2E—Special Authorized Uses of GMVs for Permanent Party Mission Support 22

2.10. Mission-Specific Authorizations. ............................................................................ 22

2.11. MAJCOM, Numbered Air Force, and Installation Commanders. ........................... 22

2.12. Operations Group Commanders (OG/CCs). ............................................................ 23

2.13. Domicile to Duty (DTD). ......................................................................................... 23

Section 2F—Dependent and Pet or Service Animal Transportation Support 23

2.14. General Dependent Transportation Support. ........................................................... 23

2.15. Invitational Travel Authorization Special Dependent Transportation Support. ...... 23

2.16. Pet and Service Animal Transportation Support. ..................................................... 24

Section 2G—DoD Agency Transportation Support (non-inclusive) 24

2.17. Civil Air Patrol Support. .......................................................................................... 24

Section 2H—General Unauthorized uses of Air Force Vehicles (Note: This is not an exclusive

list) 24

2.18. Miscellaneous Event Support. ................................................................................. 24

2.19. Personal or Social Engagements. ............................................................................. 24

2.20. Household Goods Movement. ................................................................................. 24

2.21. GMV Parking Locations. ......................................................................................... 25

2.22. Permissive TDY Status. ........................................................................................... 25

4 AFMAN24-306 30 JULY 2020

Chapter 3—LICENSING AND TRAINING 26

Section 3A—Operator Records and Licensing (OR&L) General Information and Administration 26

3.1. Policy. ...................................................................................................................... 26

3.2. OR&L Office. .......................................................................................................... 26

3.3. Driver Records. ........................................................................................................ 26

3.4. Military and Civilian Employee Licensing. ............................................................. 27

Section 3B—Licensing for Military Personnel 29

3.5. Military Personnel. ................................................................................................... 29

Section 3C—Licensing for Non-US Citizens 29

3.6. Qualifying a Non-US Citizen. .................................................................................. 29

Section 3D—Commercial Drivers License Requirements 29

3.7. Commercial Drivers License (CDL). ....................................................................... 30

3.8. Military Exemption. ................................................................................................. 30

Section 3E—Licensing for Federal Civilian Employees, Contractor Personnel, and Federal Prison

Camp Inmates 30

3.9. Licensing Federal Civilian Employees. ................................................................... 30

3.10. Licensing Contractor Personnel. .............................................................................. 31

3.11. Requirements for Contingency and Remote Areas. ................................................. 32

Section 3F—Administrative Control of USAF Licensing 32

3.12. Suspension for Substance Abuse. ............................................................................ 32

3.13. Reinstatement of a State Operator’s Permit. ............................................................ 32

Section 3G—Operator Certification and Administrative Responsibility 32

3.14. Operator Certification. ............................................................................................. 32

Section 3H—Vehicle Training Aid Requirements 32

3.15. Air Force Qualification Training Packages (AFQTPs). ........................................... 32

Section 3I—Unit Vehicle Training and Vehicle Control Official (VCO) Responsibilities 34

3.16. Policy. ...................................................................................................................... 34

3.17. TDY Vehicle Training and Qualifications. .............................................................. 35

AFMAN24-306 30 JULY 2020 5

Chapter 4—BASIC OPERATING PROCEDURES AND MANEUVERS 36

Section 4A—General Information 36

4.1. Objective. ................................................................................................................. 36

4.2. Basic Responsibilities. ............................................................................................. 36

Section 4B—Basic Unit/VCO Responsibilities 36

4.3. Unit/VCO Responsibilities. ..................................................................................... 36

4.4. Toll Tickets/Transponders. ...................................................................................... 37

Section 4C—Operator of Air Force GMVs Health and Well-Being 37

4.5. Operator Health and Well-Being. ............................................................................ 37

Section 4D—Manual and Semi-automatic Transmissions Operation 37

4.6. Starting. .................................................................................................................... 37

4.7. General Information. ................................................................................................ 37

4.8. Clutch Operation. ..................................................................................................... 37

4.9. Manual Shifting Purpose. ........................................................................................ 38

4.10. Clutch Shifting Procedure. ....................................................................................... 38

4.11. Double-Clutch Shifting Procedure. .......................................................................... 39

4.12. Spark Ignition Engine Braking Operation. .............................................................. 39

Section 4E—Backing 40

4.13. Backing. ................................................................................................................... 40

Section 4F—Spotter Safety 40

4.14. Spotter Safety. .......................................................................................................... 40

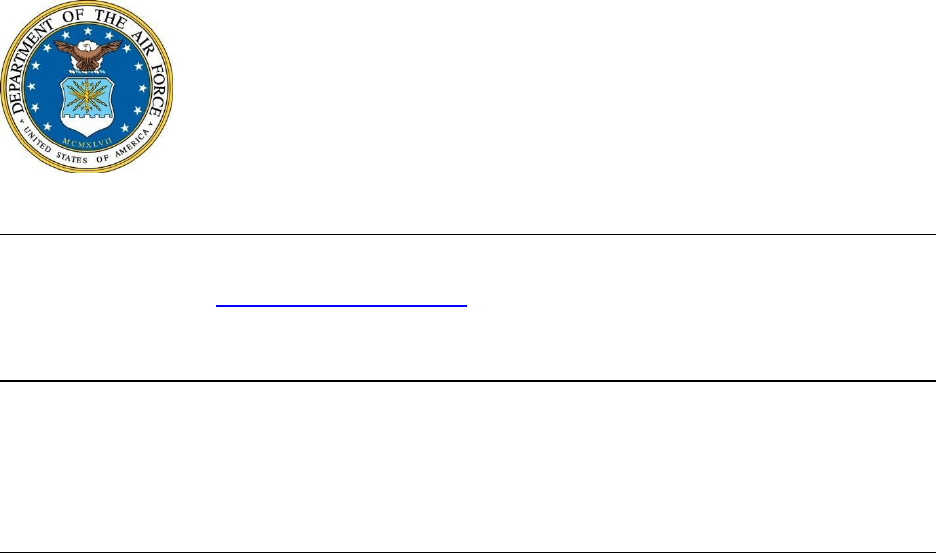

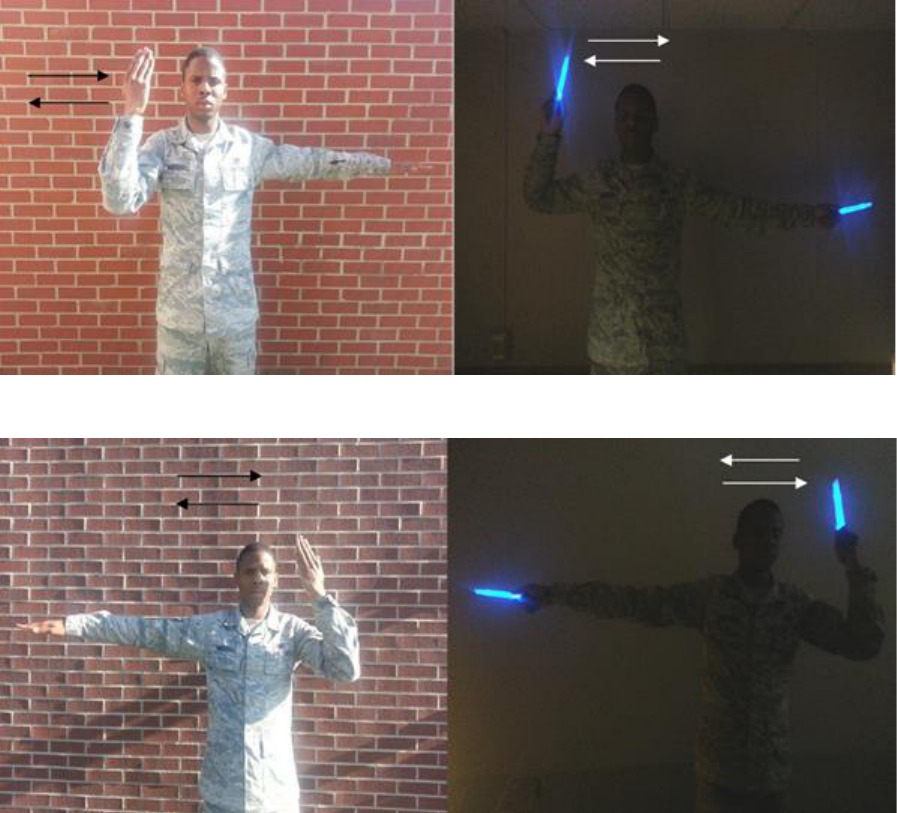

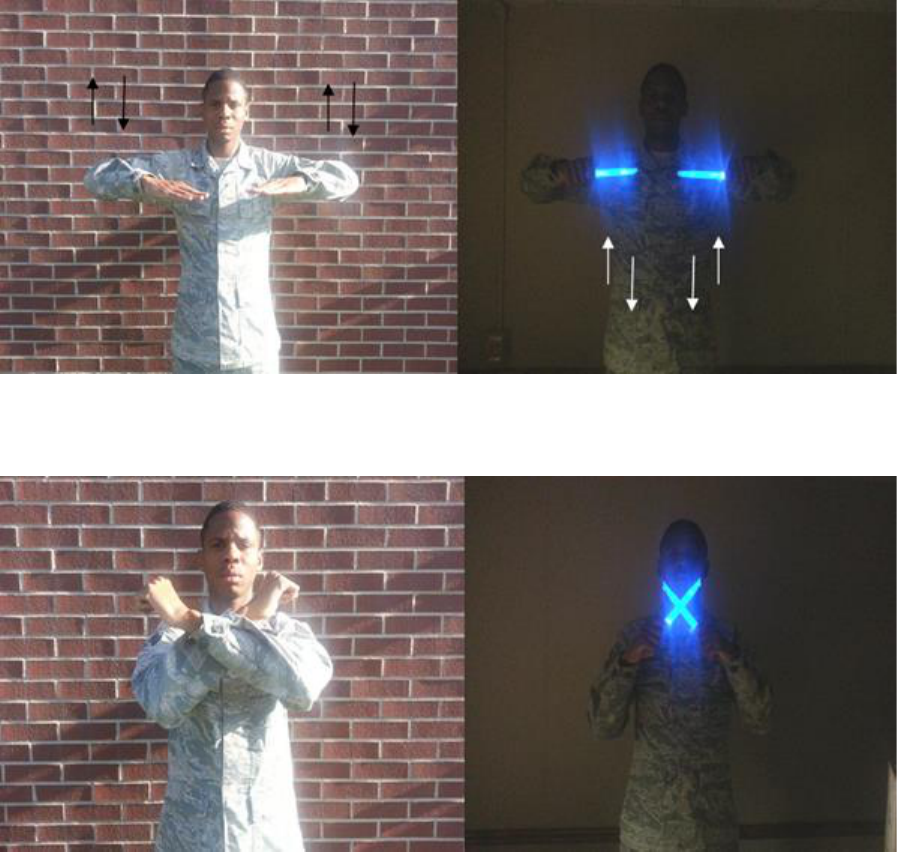

4.15. Air Force Standard Spotting Hand and Arm Signals. .............................................. 41

Figure 4.1. Standard Spotting Hand and Arm Signals – Come Towards the Spotter. ............... 42

Figure 4.2. Standard Spotting Hand and Arm Signals – Move Away from the Spotter. ........... 42

Figure 4.3. Standard Spotting Hand and Arm Signals. .............................................................. 43

Figure 4.4. Standard Spotting Hand and Arm Signals. .............................................................. 43

Figure 4.5. Standard Spotting Hand and Arm Signals – Slow Down. ....................................... 44

Figure 4.6. Standard Spotting Hand and Arm Signals – Stop. ................................................... 44

Figure 4.7. Standard Spotting Hand and Arm Signals – Shut Down. ........................................ 45

6 AFMAN24-306 30 JULY 2020

Section 4G—Parking 45

4.16. General. .................................................................................................................... 45

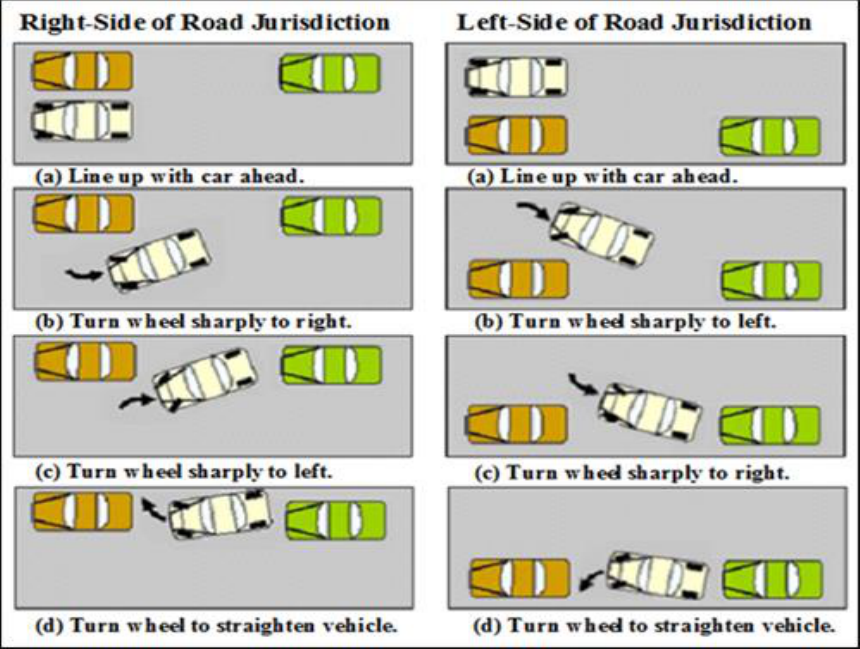

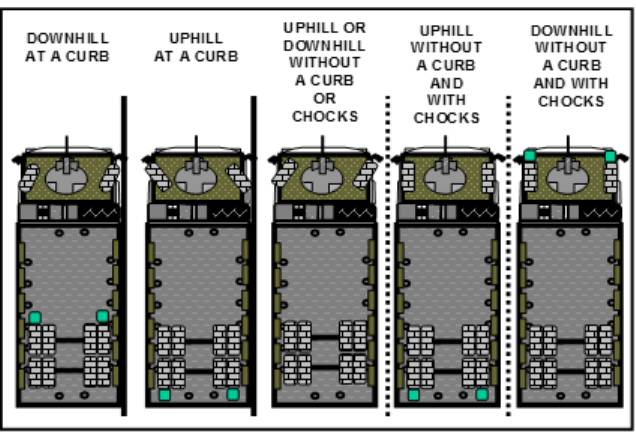

Figure 4.8. Parking Parallel to a Curb. ....................................................................................... 47

4.17. Diagonal or Angle Parking. ..................................................................................... 47

Figure 4.9. Parking on a Hill. ..................................................................................................... 48

Chapter 5—PROCEDURES FOR TRANSPORTING PERSONNEL 49

Section 5A—General Information and Procedures 49

5.1. General Information. ................................................................................................ 49

5.2. General Procedures. ................................................................................................. 49

Section 5B—Special Situations 49

5.3. Distinguished Visitors (DVs). .................................................................................. 49

5.4. Emergency Vehicles. ............................................................................................... 50

Chapter 6—MAINTAINING SAFE VEHICLES 51

Section 6A—General Maintenance Responsibilities 51

6.1. General Information. ................................................................................................ 51

6.2. Fuel-Efficient Operations......................................................................................... 51

6.3. DOD Fleet Card Program. ....................................................................................... 51

6.4. Use Overview. ......................................................................................................... 51

Section 6B—Armored Vehicle and Preventative Maintenance 52

6.5. Armored Vehicle Maintenance. ............................................................................... 52

Section 6C—Operation Inspections 52

6.6. Overview Operation Inspections. ............................................................................. 52

Section 6D—Air Force Equipment and Maintenance Forms and Records 52

6.7. Air Force Equipment and Maintenance Forms and Records. .................................. 52

6.8. Defects. .................................................................................................................... 52

Chapter 7—HAZARDS AND SAFETY INFORMATION 54

Section 7A—General Hazards and Safety Information 54

7.1. General. .................................................................................................................... 54

AFMAN24-306 30 JULY 2020 7

Section 7B—Hazards and Safety Measures 54

7.2. Vehicle Hazards. ...................................................................................................... 54

7.3. Pedestrians. .............................................................................................................. 54

7.4. Bicyclists. ................................................................................................................. 55

7.5. Motorcyclists. .......................................................................................................... 55

7.6. Animals. ................................................................................................................... 55

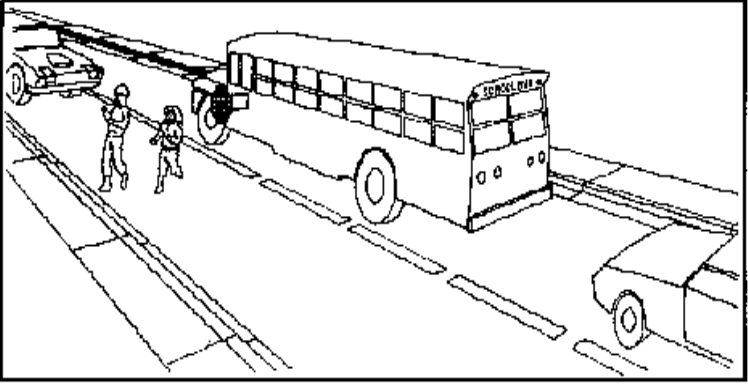

7.7. School Buses. ........................................................................................................... 55

Figure 7.1. Stopping for a School Bus. ...................................................................................... 56

7.8. Emergency Vehicles. ............................................................................................... 56

7.9. Weather Hazards. ..................................................................................................... 56

7.10. Secondary Roads. ..................................................................................................... 61

7.11. Overloading and Overcrowding. .............................................................................. 61

Section 7C—Off-Road Driving 62

7.12. General Information. ................................................................................................ 62

7.13. Off-Road Driving Terrain Types. ............................................................................ 62

7.14. Vehicle Care. ........................................................................................................... 66

Chapter 8—ROADSIDE EMERGENCY AND ACCIDENT RESPONSE 67

Section 8A—General Information 67

8.1. General Information. ................................................................................................ 67

Section 8B—Roadside Emergencies 67

8.2. Tire Blowouts. ......................................................................................................... 67

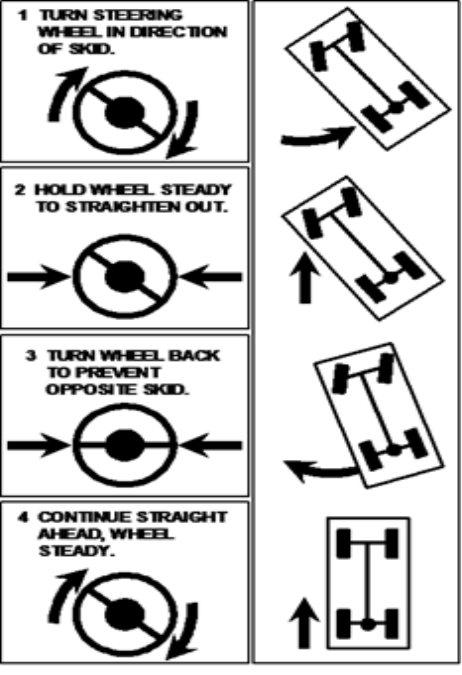

8.3. Skids. ....................................................................................................................... 67

Figure 8.1. Recovering from a Skid. .......................................................................................... 68

8.4. Running Off the Pavement. ..................................................................................... 68

8.5. Brake Failure. ........................................................................................................... 69

8.6. Breakdowns. ............................................................................................................ 69

Section 8C—Vehicle Fires 69

8.7. Preventing Vehicle Fires. ......................................................................................... 69

8.8. Fighting Vehicle Fires. ............................................................................................ 70

8 AFMAN24-306 30 JULY 2020

Section 8D—Roadside Tool Kits 71

8.9. Spare Tire and Tool Kit. .......................................................................................... 71

8.10. Highway Warning Kit. ............................................................................................. 71

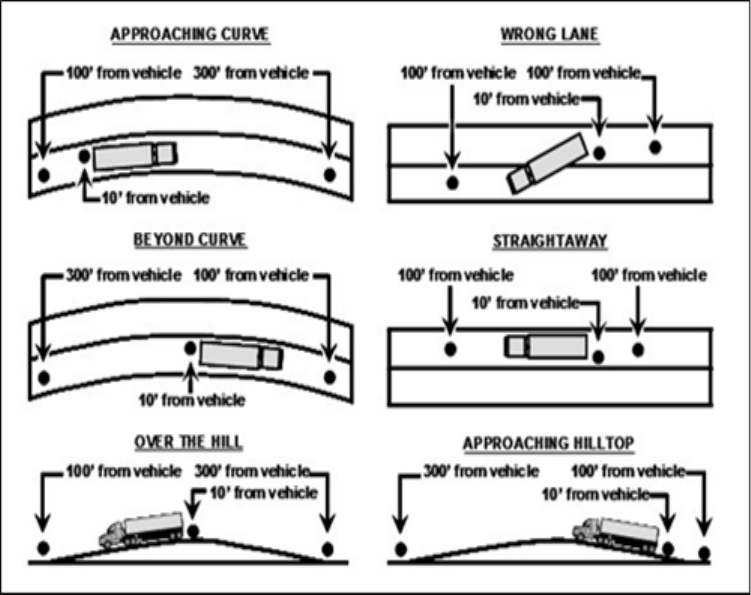

Figure 8.2. Use of Highway Warning Kits. ................................................................................ 72

8.11. Use of Highway Warning Kit. ................................................................................. 72

Section 8E—Off-Base Repair Service 73

8.12. Off-Base Repair Service. ......................................................................................... 73

Section 8F—Accident Response 73

8.13. Initial Accident Response Procedures. .................................................................... 73

8.14. Precautions Against Further Accidents. ................................................................... 74

8.15. Removal of Vehicle From Accident Scene. ............................................................. 74

Section 8G—Preparation of Accident Forms 75

8.16. Preparation of Accident Forms. ............................................................................... 75

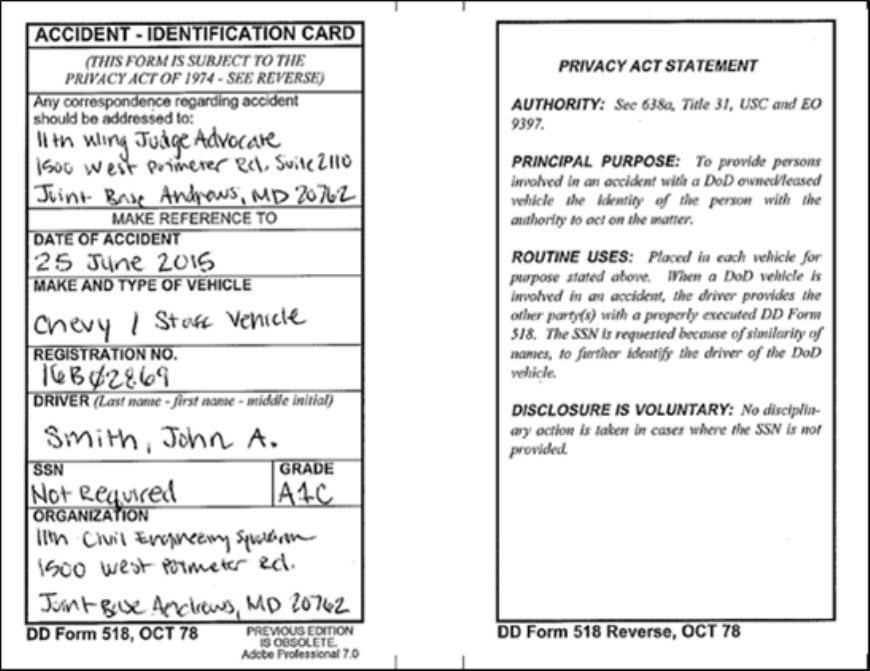

Figure 8.3. DD Form 518. .......................................................................................................... 75

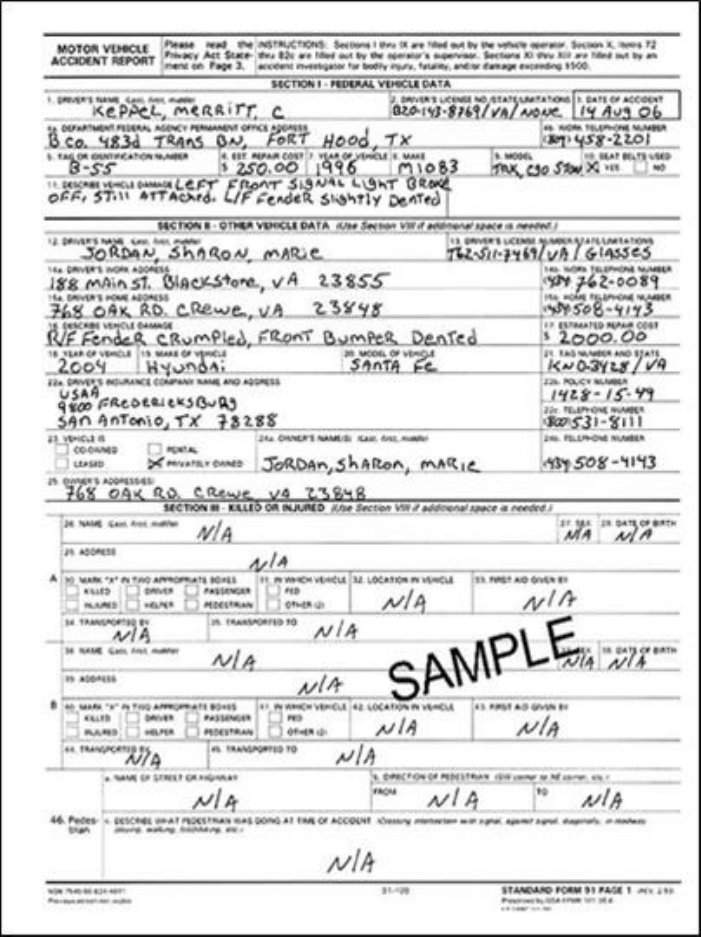

Figure 8.4. Sample Form of SF 91 (Page 1). .............................................................................. 77

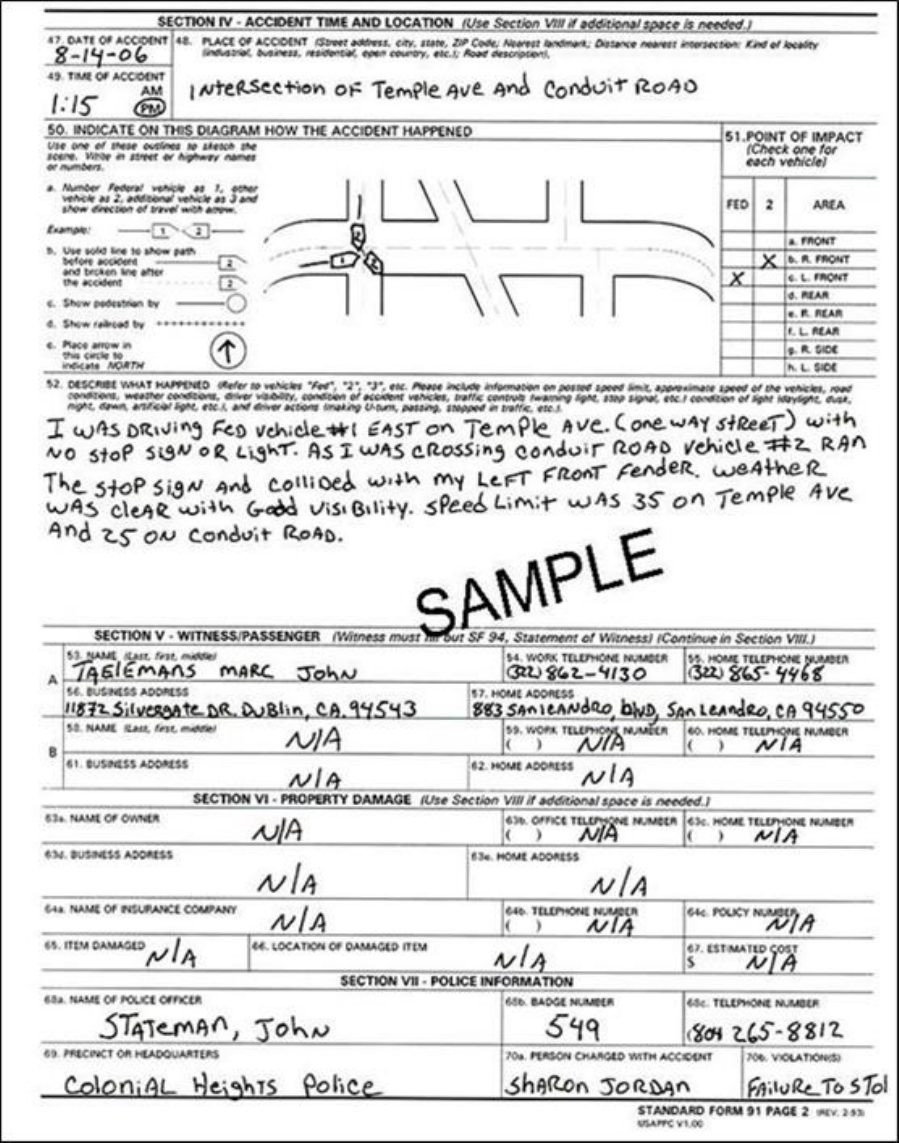

Figure 8.5. Sample Form of SF 91 (Page 2). .............................................................................. 78

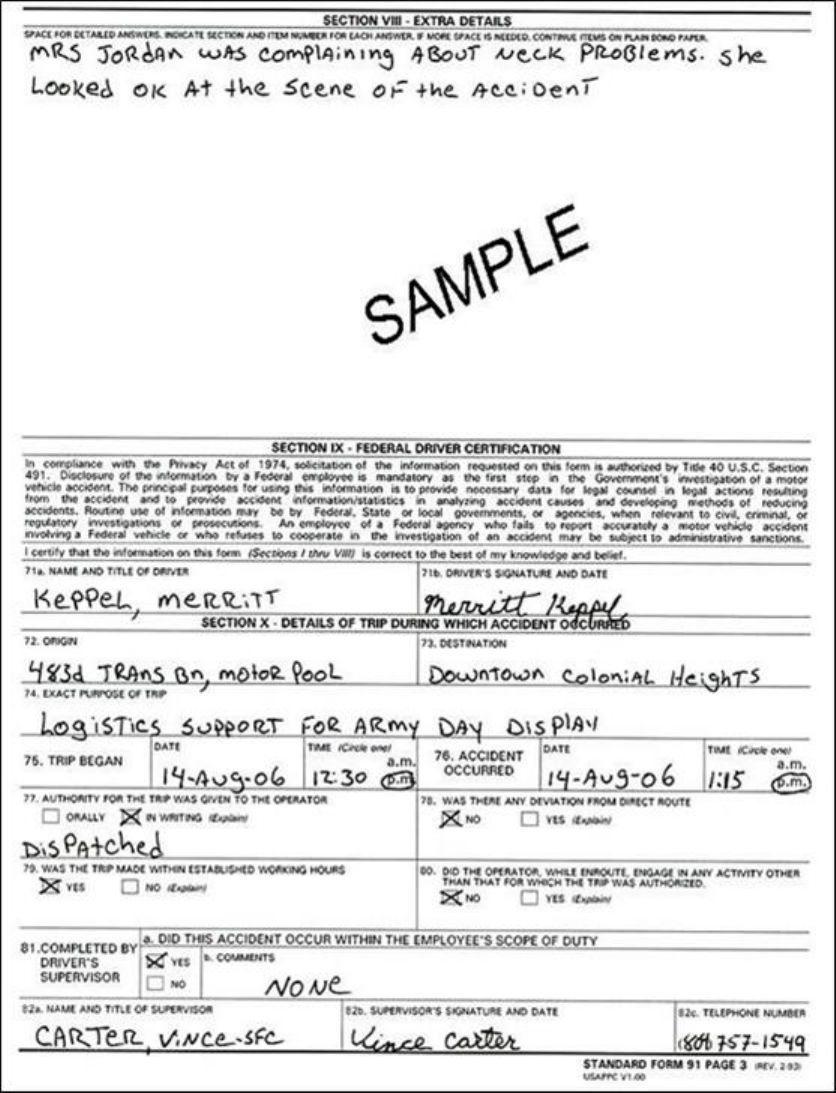

Figure 8.6. SF Form 91 (Page 3). ............................................................................................... 79

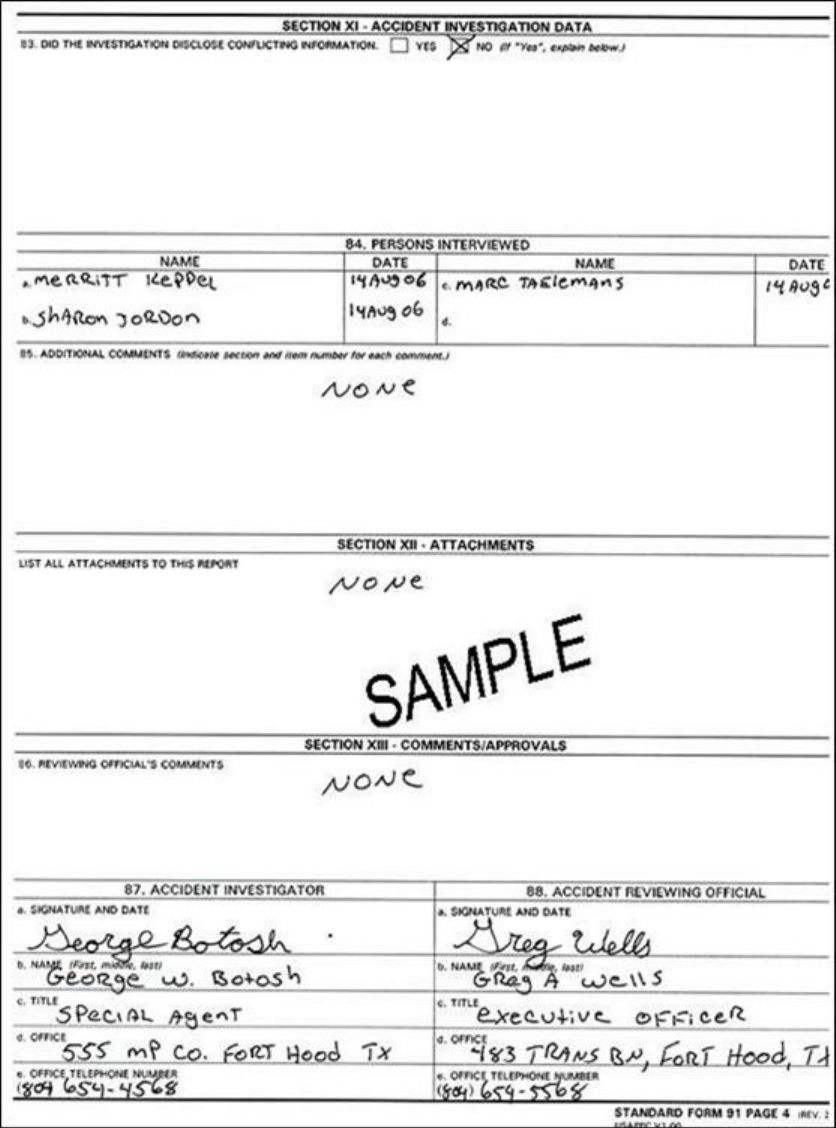

Figure 8.7. SF Form 91 (Page 4). ............................................................................................... 80

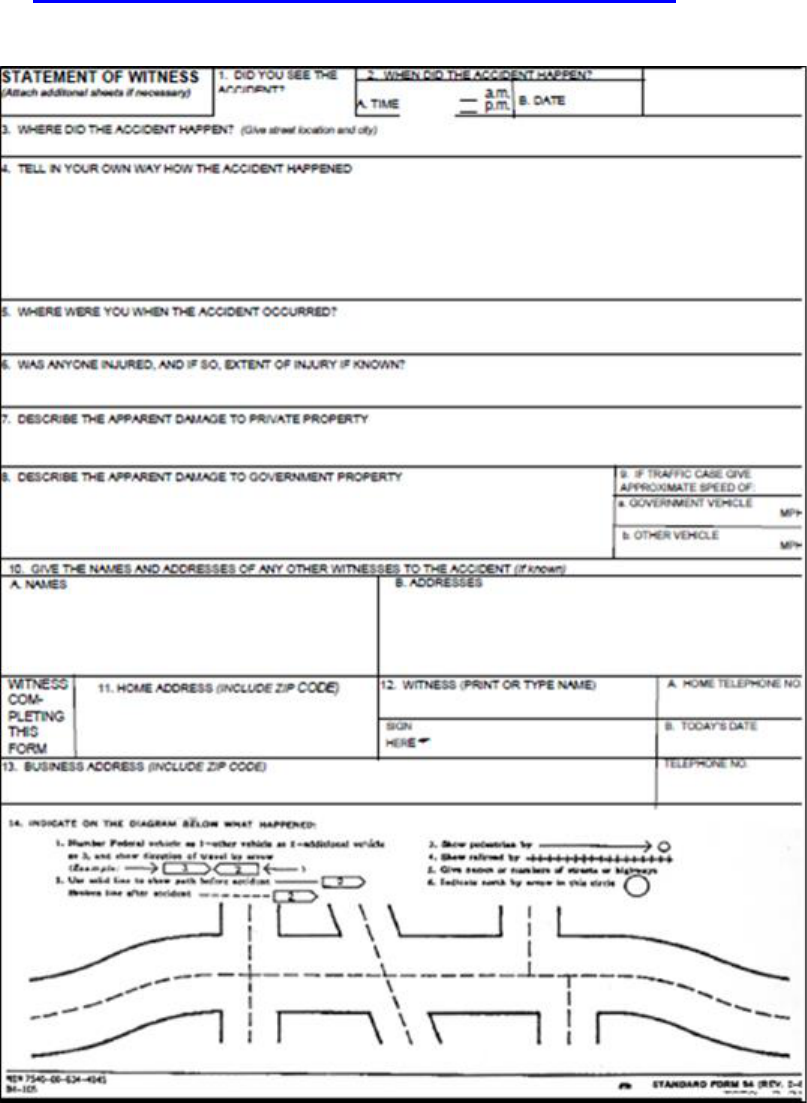

Figure 8.8. SF Form 94. ............................................................................................................. 81

Chapter 9—LOADING AND TIE-DOWN PROCEDURES 82

Section 9A—Loading and Tie-down Procedures General Information 82

9.1. General Information. ................................................................................................ 82

Section 9B—Cargo Responsibility and Distribution 82

9.2. Responsibility for Cargo. ......................................................................................... 82

9.3. Distribution of Cargo. .............................................................................................. 83

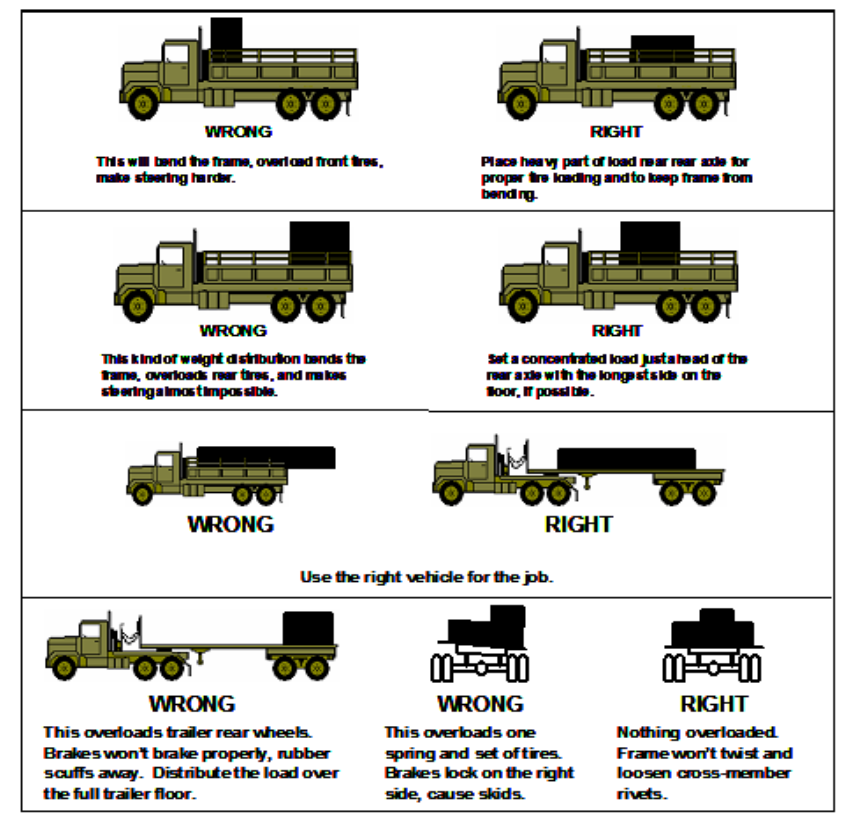

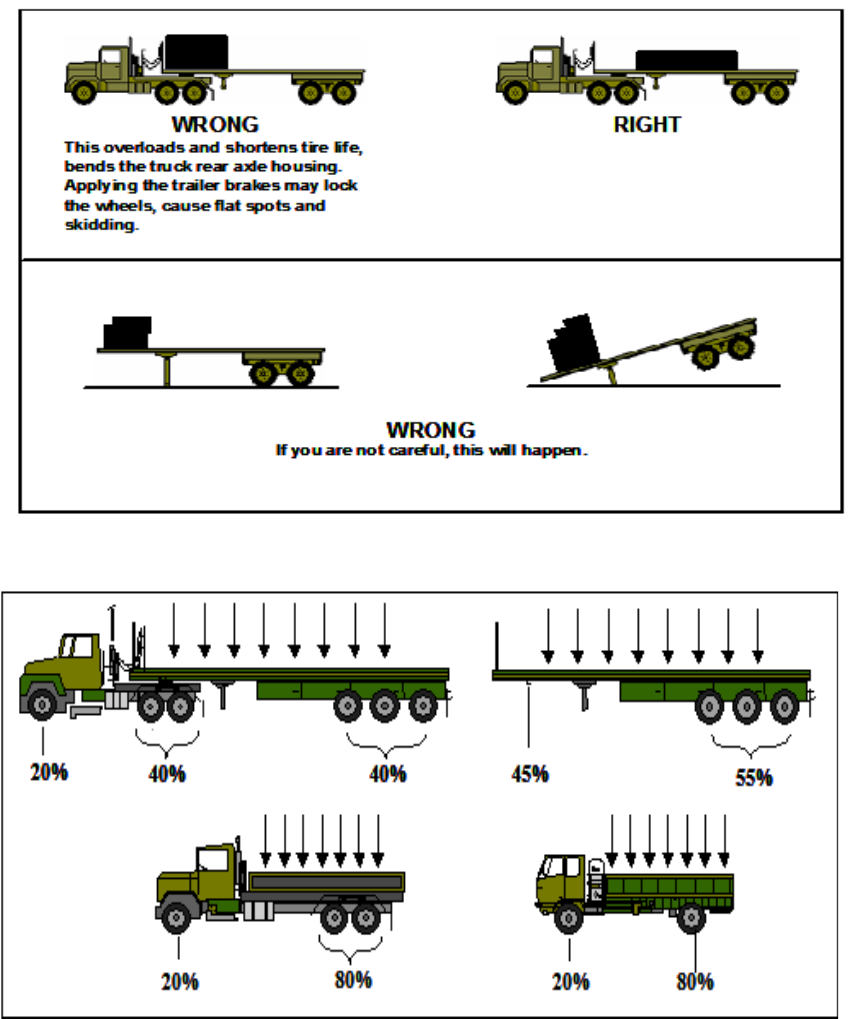

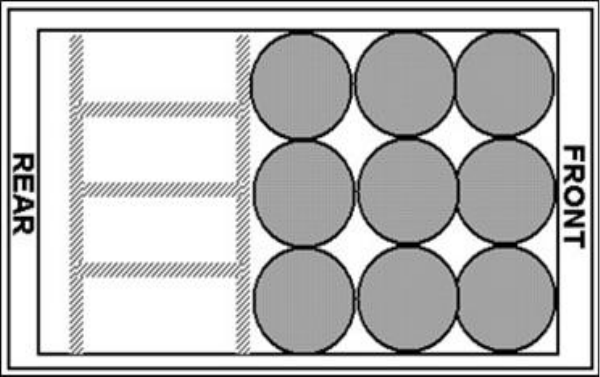

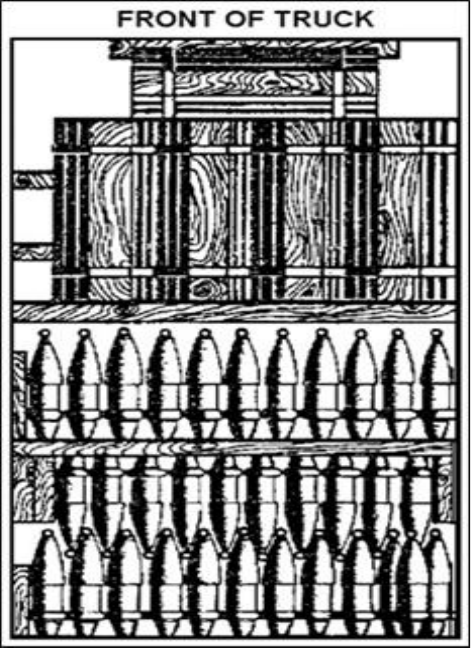

Figure 9.1. Load Distribution. .................................................................................................... 84

Figure 9.2. Load Distribution (Continued). ................................................................................ 85

Figure 9.3. Load Distribution (continued). ................................................................................. 85

9.4. Loading and Tie-down Safety. ................................................................................. 85

AFMAN24-306 30 JULY 2020 9

9.5. Vehicle Safety Standards. ........................................................................................ 86

9.6. Types of Loads. ........................................................................................................ 86

9.7. Special Loads. .......................................................................................................... 87

9.8. Load Compatibility. ................................................................................................. 87

9.9. Load Configuration. ................................................................................................. 87

9.10. Perishable Cargo. ..................................................................................................... 88

9.11. Types of Tie-down Devices. .................................................................................... 88

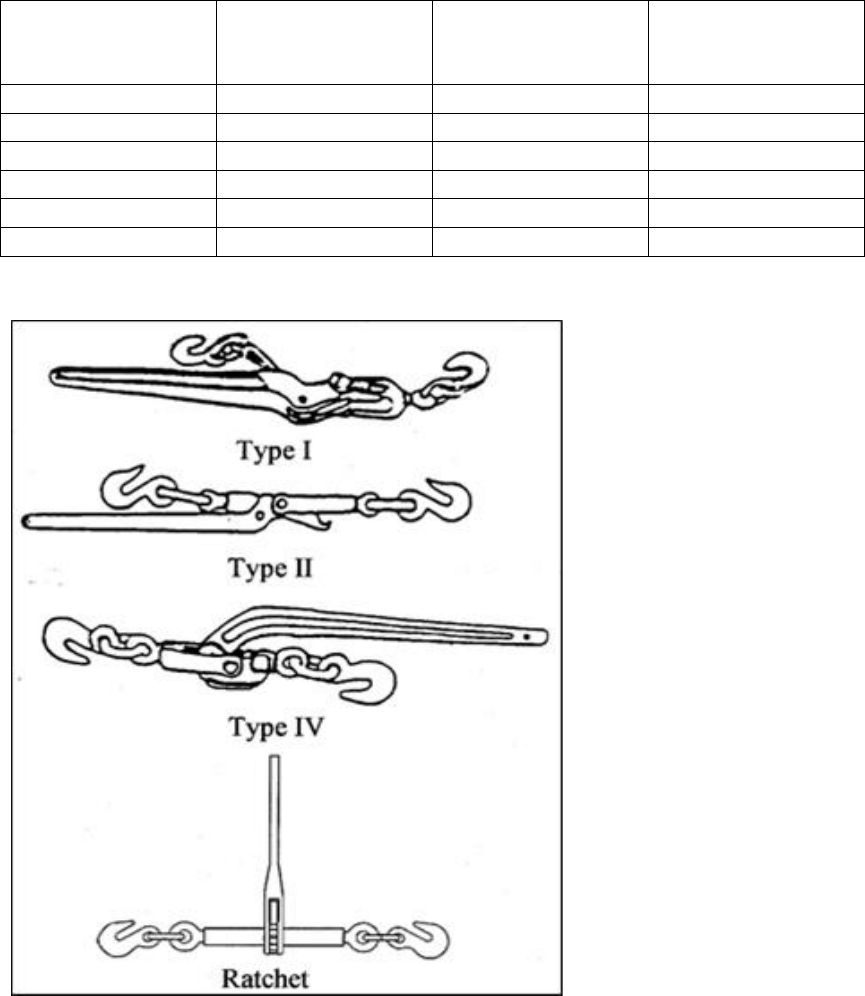

9.12. Load binders. ........................................................................................................... 89

9.13. Chains. ..................................................................................................................... 89

Table 9.1. Chain Characteristics. .............................................................................................. 90

Figure 9.4. Types of Load binders. ............................................................................................ 90

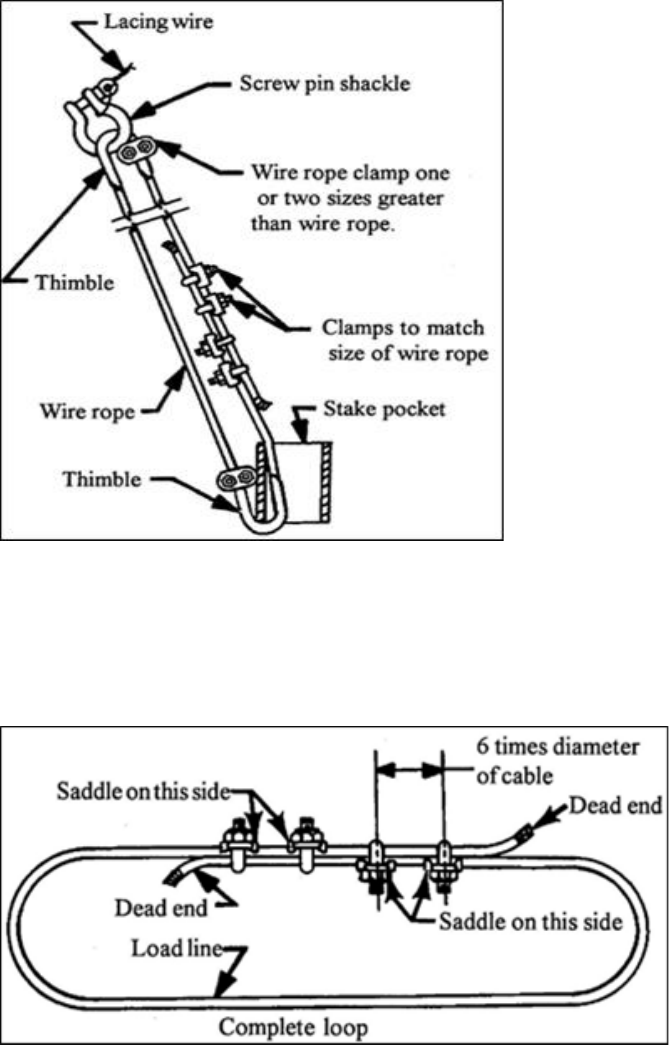

9.14. Wire Rope. ............................................................................................................... 90

Figure 9.5. Wire Rope. ............................................................................................................... 91

9.15. U-Bolts (Clamps). .................................................................................................... 91

Figure 9.6. U-Clamps. ................................................................................................................ 91

Table 9.2. Wire Rope Characteristics. ...................................................................................... 92

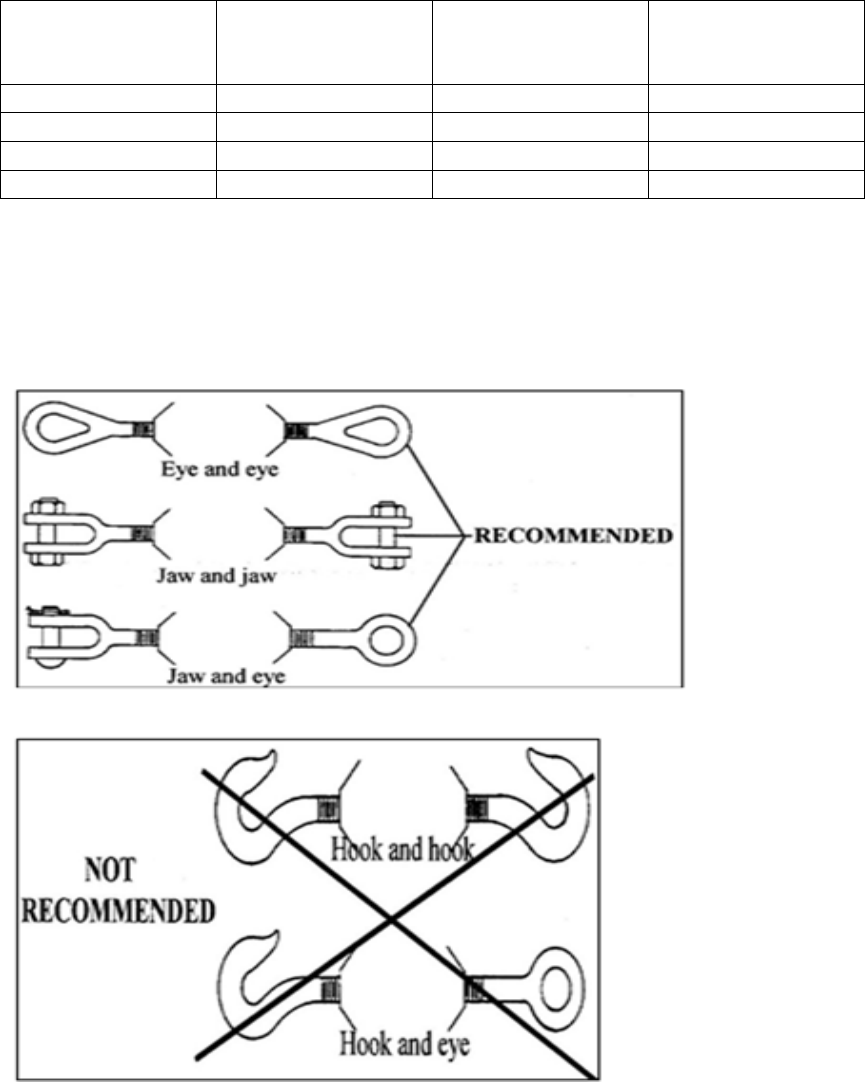

9.16. Turnbuckles. ............................................................................................................ 92

Figure 9.7. Turnbuckle Types. ................................................................................................... 92

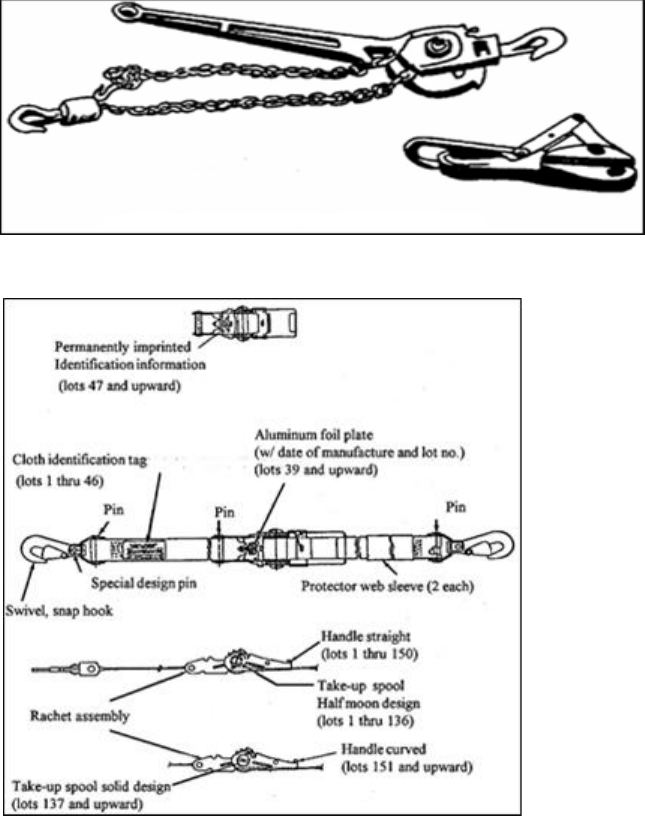

9.17. Chain-Hoist and Cable Grippers. ............................................................................. 93

9.18. Web-Style Ratchet and Strap Assemblies. ............................................................... 93

Figure 9.8. Cable Grippers and Chain Hoist. ............................................................................. 93

Figure 9.9. Web-Style Strap and Ratchet Assemblies. ............................................................... 93

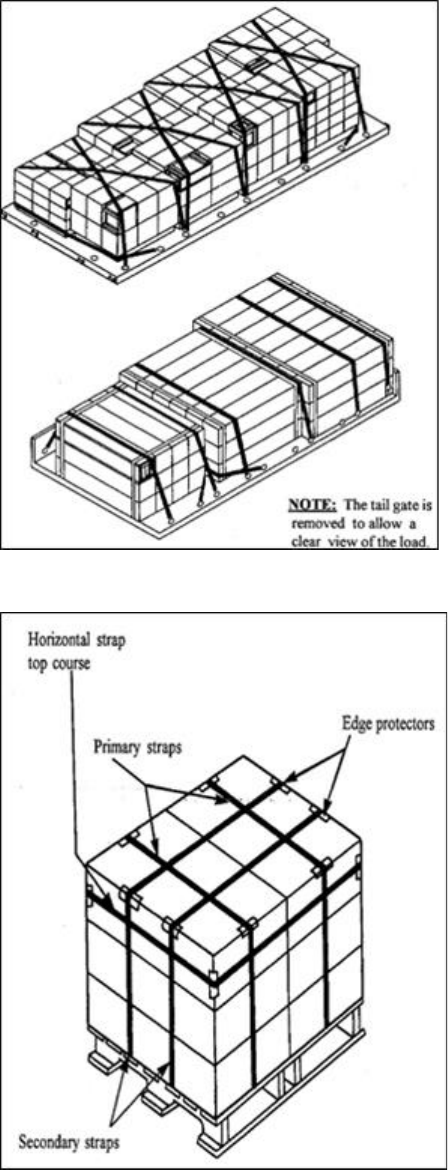

Figure 9.10. Strap-Secured Load. ................................................................................................. 94

Figure 9.11. Strap or Banded Load. ............................................................................................. 94

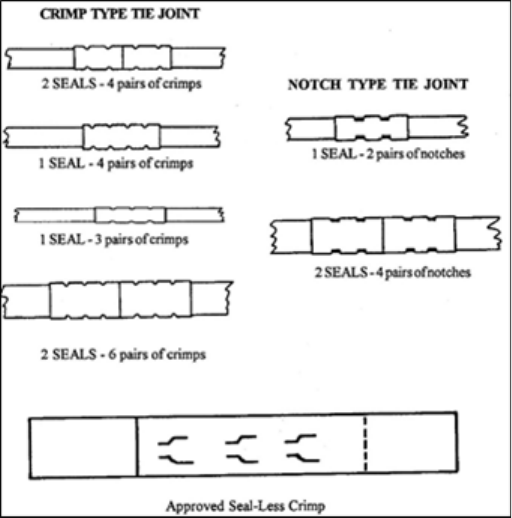

9.19. Steel Banding. .......................................................................................................... 95

Figure 9.12. Crimp Type Joints. ................................................................................................... 95

Figure 9.13. Load Secured by Steel Banding. ............................................................................. 96

9.20. Inspection of the Load. ............................................................................................ 96

9.21. Inspection of Tie-down Equipment. ........................................................................ 97

10 AFMAN24-306 30 JULY 2020

Table 9.3. Load binder Inspection Criteria. .............................................................................. 97

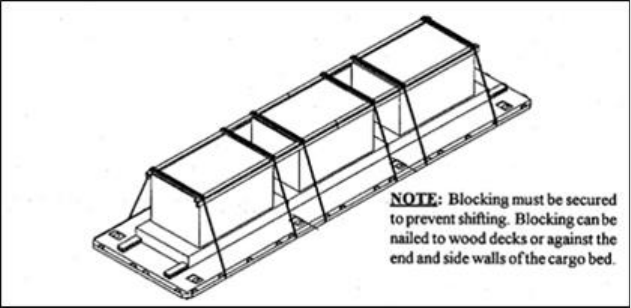

9.22. Transferring the Load. ............................................................................................. 98

9.23. Blocking and Bracing. ............................................................................................. 99

Figure 9.14. Bracing a Load of Barrels. ....................................................................................... 99

Figure 9.15. Load Arrangement of Ammunition. ........................................................................ 100

9.24. General Rules for Blocking and Bracing. ................................................................ 100

9.25. Securing the Load. ................................................................................................... 100

9.26. Using Web Straps. ................................................................................................... 101

9.27. Chains and Load binders. ......................................................................................... 101

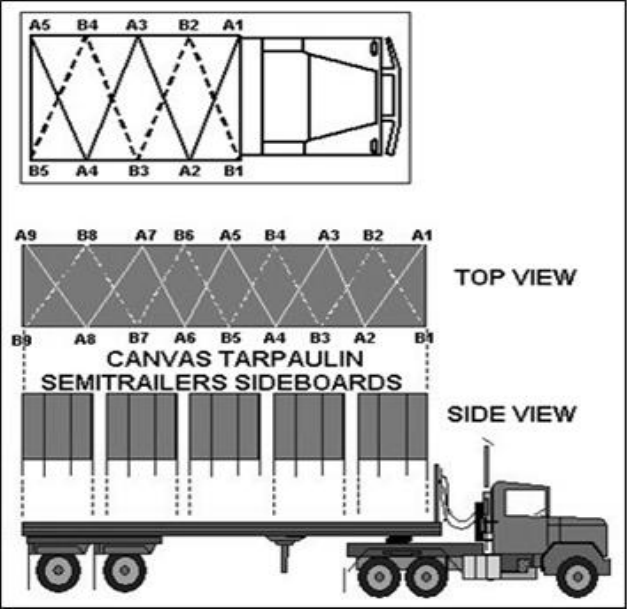

9.28. Load Lashing. .......................................................................................................... 101

Figure 9.16. Load Lashing. .......................................................................................................... 102

Chapter 10—DANGEROUS/HAZARDOUS CARGO AND MATERIALS 103

Section 10A—Transporting Dangerous/Hazardous Cargo 103

10.1. General Information. ................................................................................................ 103

10.2. Necessary Forms. ..................................................................................................... 103

Section 10B—General Safety Measures 103

10.3. General Safety Measures. ........................................................................................ 103

Section 10C—Rules for Transporting Dangerous/Hazardous Cargo 104

10.4. Rules for Transporting Dangerous/Hazardous Cargo. ............................................. 104

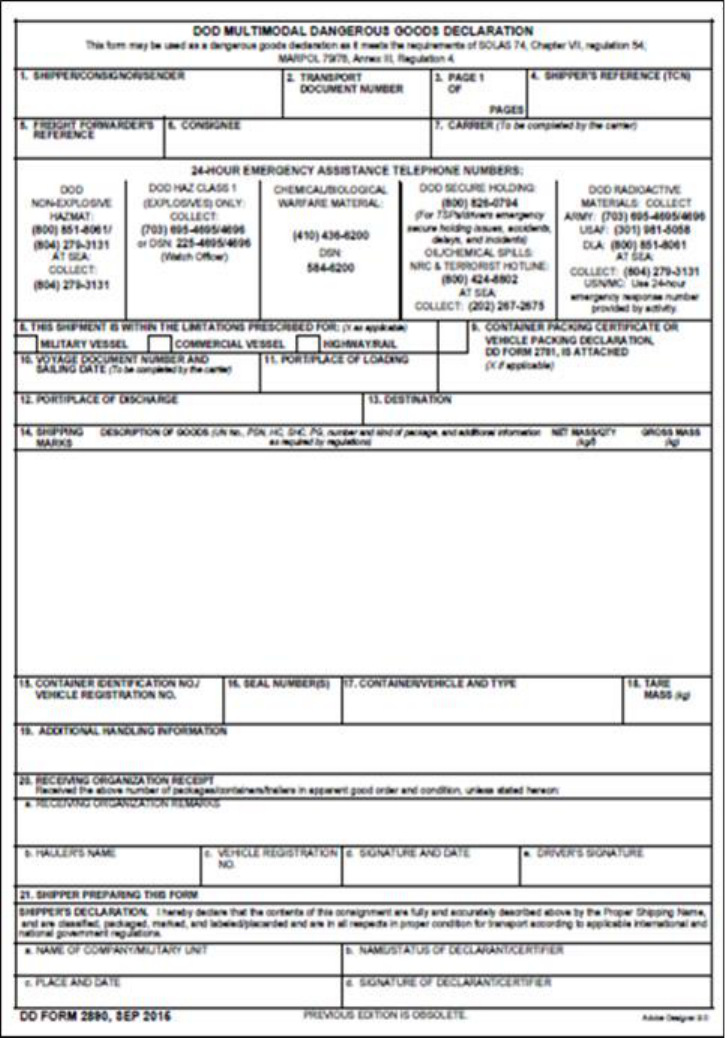

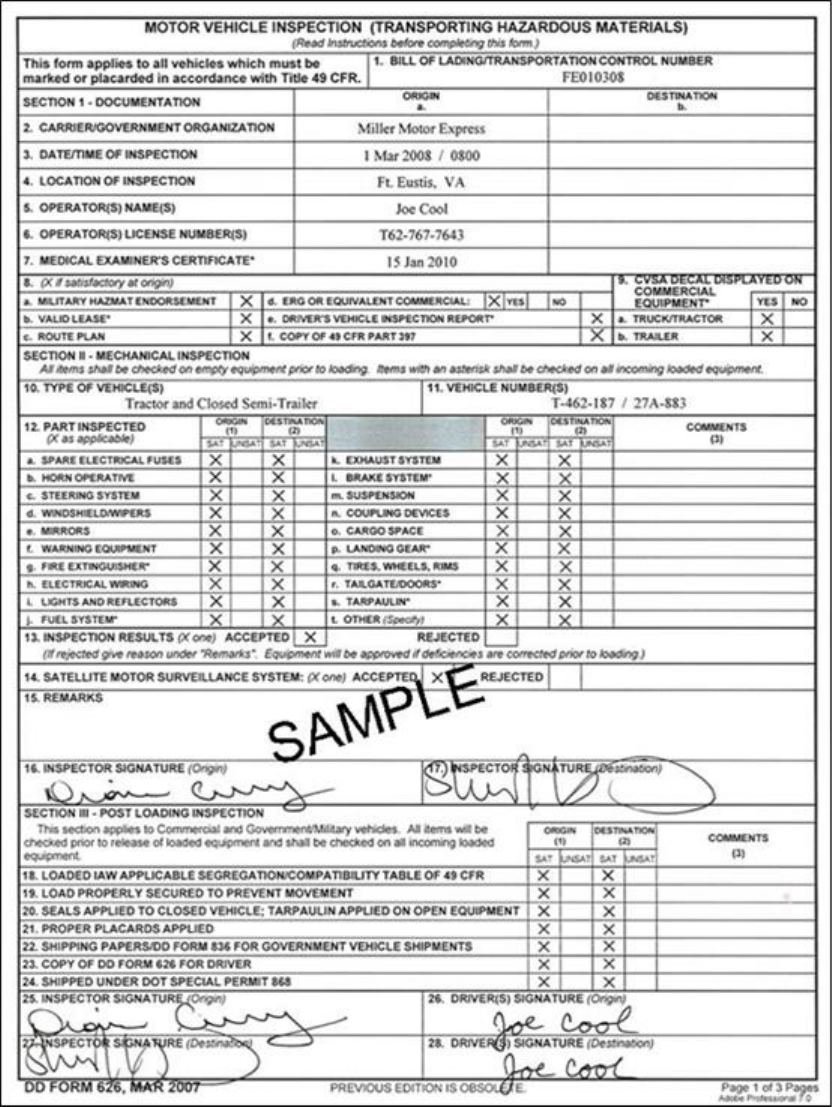

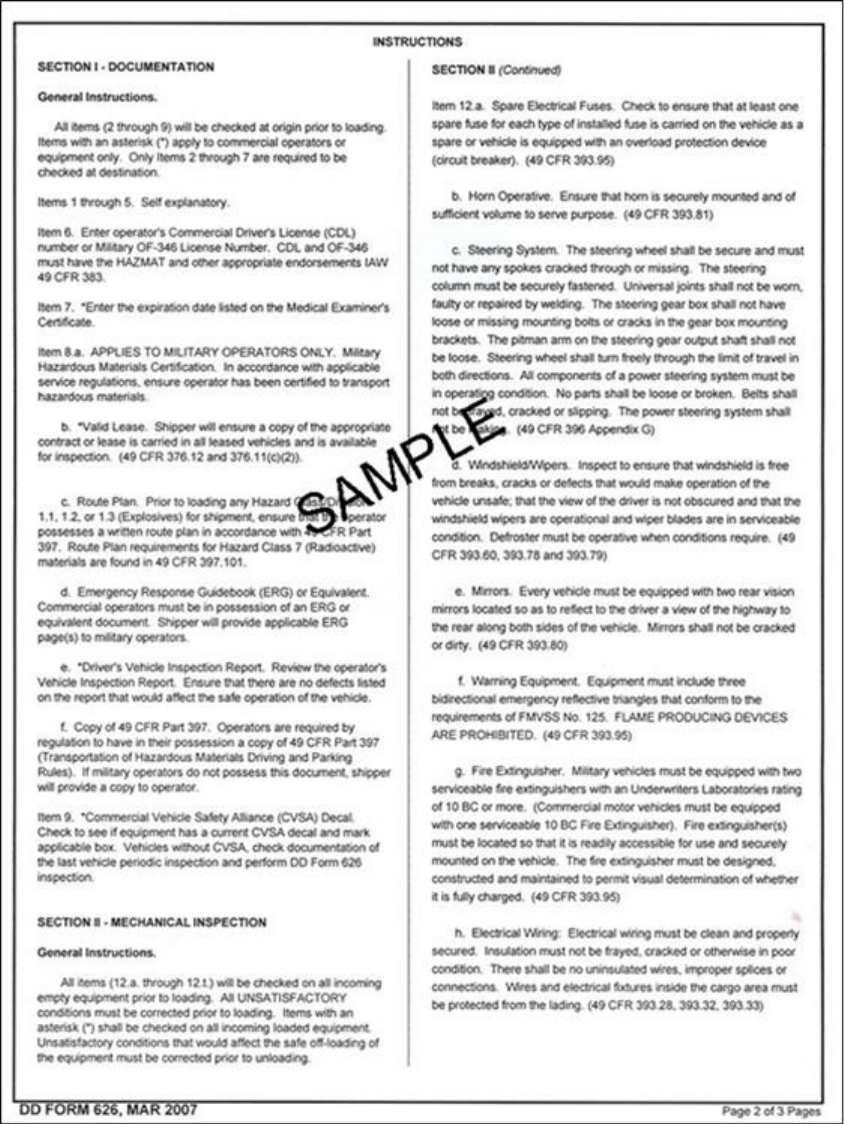

Figure 10.1. DD Form 2890 (Page 1). .......................................................................................... 106

Figure 10.2. DD Form 2890 (Page 2). .......................................................................................... 107

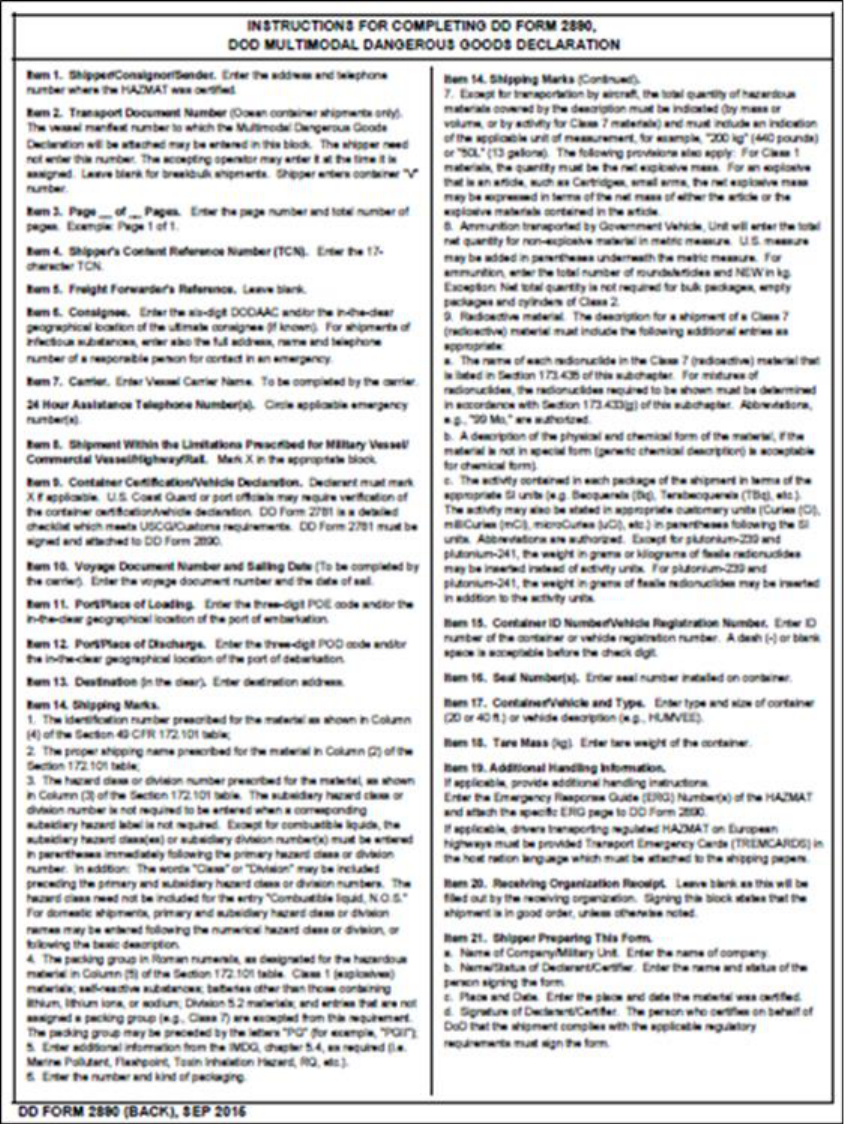

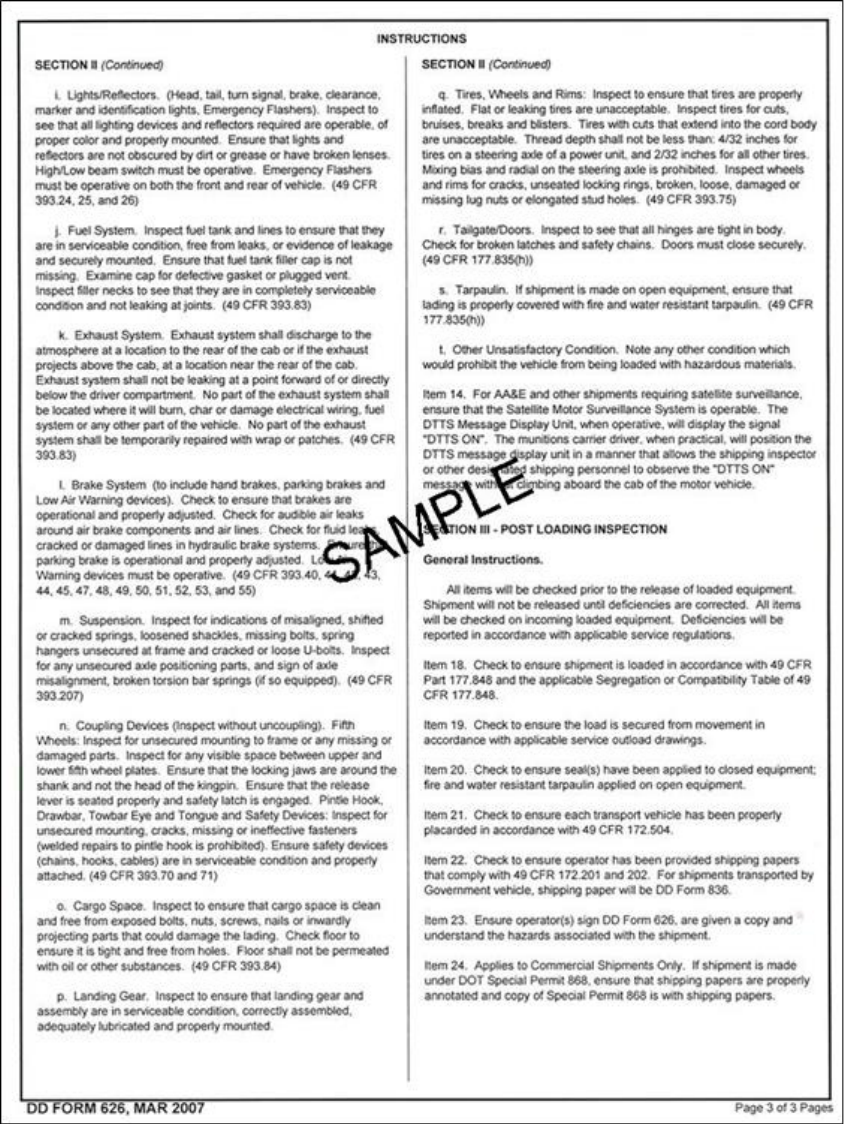

Figure 10.3. DD Form 626 (Page 1). ............................................................................................ 108

Figure 10.4. DD Form 626 (Page 2). ............................................................................................ 109

Figure 10.5. DD Form 626 (Page 3). ............................................................................................ 110

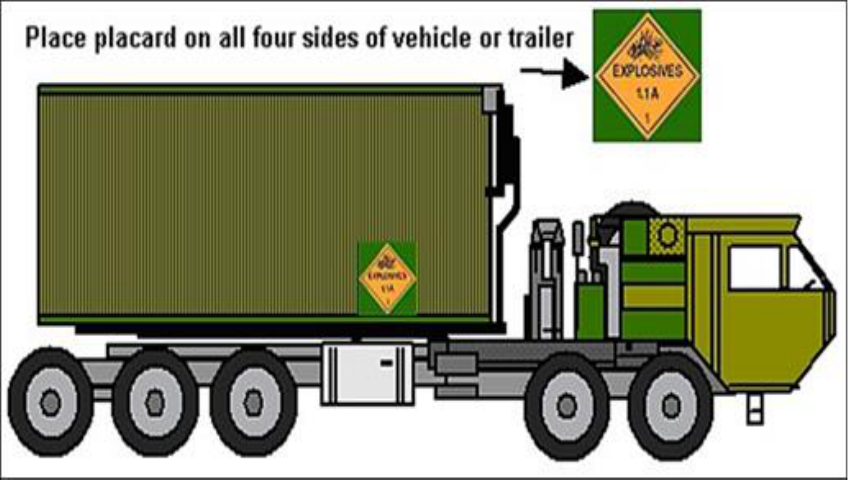

Figure 10.6. Placarding a Vehicle. ............................................................................................... 111

10.5. HAZMAT Routes. ................................................................................................... 111

10.6. Operator Responsibilities. ........................................................................................ 111

Section 10D—Load Custody 111

10.7. Load Custody. .......................................................................................................... 111

AFMAN24-306 30 JULY 2020 11

10.8. Parking. .................................................................................................................... 112

10.9. Missiles. ................................................................................................................... 112

10.10. Ammunition and Explosives. ................................................................................... 112

10.11. Chemical Agents. ..................................................................................................... 113

Section 10E—Transporting HAZMAT by Highway 113

10.12. Transporting HAZMAT by Highway. ..................................................................... 113

Section 10F—Detecting Fuel Leakage Occurring On a Public Highway 114

10.13. Detecting Fuel Leakage Occurring On a Public Highway. ...................................... 114

Section 10G—Detecting Fuel Leakage Occurring Off the Road 114

10.14. Detecting Fuel Leakage Occurring Off the Road. ................................................... 114

10.15. Petroleum Tank Vehicles Safety Procedures. .......................................................... 115

Chapter 11—VEHICLE RECOVERY OVERVIEW 116

Section 11A—Vehicle Recovery General Information 116

11.1. General Information. ................................................................................................ 116

Section 11B—Recovery Safety 116

11.2. Recovery Safety. ...................................................................................................... 116

Section 11C—Common Tools for Recovery 116

11.3. Common Tools for Recovery................................................................................... 116

Section 11D—Spotters for Recovery 117

11.4. Spotters for Recovery. ............................................................................................. 117

Section 11E—Towing Vehicles With Bars 117

11.5. Towing Statement. ................................................................................................... 117

11.6. General Rules for Towing. ....................................................................................... 117

Section 11F—Anchoring Vehicles 118

11.7. Anchoring Vehicles. ................................................................................................ 118

Section 11G—Winch Recovery 118

11.8. Winch Recovery. ..................................................................................................... 118

12 AFMAN24-306 30 JULY 2020

Chapter 12—CONTINGENCY OPERATIONS OVERVIEW 119

Section 12A—Motor Marches and Convoys General Information 119

12.1. General Information. ................................................................................................ 119

Section 12B—Motor Marches and Convoys Overview 119

12.2. Rate-of-Speed and Interval. ..................................................................................... 119

12.3. Vehicle Failures. ...................................................................................................... 120

12.4. Vehicle Halts. ........................................................................................................... 120

12.5. Convoy Security. ..................................................................................................... 120

12.6. Convoy Control Signals. .......................................................................................... 120

12.7. NATO Convoy Flags and Signals. ........................................................................... 120

Section 12C—Vehicle Camouflage Operations 121

12.8. Camouflage Operations. .......................................................................................... 121

12.9. Stationary Vehicle Camouflage and Concealment. ................................................. 121

12.10. Camouflage Screen System. .................................................................................... 121

12.11. Erecting of Camouflage Screens Over Vehicle. ...................................................... 121

Section 12D—Vehicle Operations Using Night Vision Devices and Operations Under Blackout

(BO) Conditions 121

12.12. General Information. ................................................................................................ 121

12.13. Night Vision Goggles Introduction. ......................................................................... 121

12.14. Single Color Vision. ................................................................................................ 122

12.15. Color Adaptation. ..................................................................................................... 122

12.16. Considerations When Driving With Night Vision Goggles. .................................... 122

Table 12.1. NVG Lighting Countermeasures. ............................................................................ 124

12.17. Driving Techniques With Night Vision Goggles. .................................................... 125

12.18. Role of the Assistant GMV Operator. ...................................................................... 125

12.19. Parking Vehicles. ..................................................................................................... 126

12.20. Operations Under Blackout Conditions Without Night Vision Devices. ................ 126

12.21. Blackout Marker Lights. .......................................................................................... 126

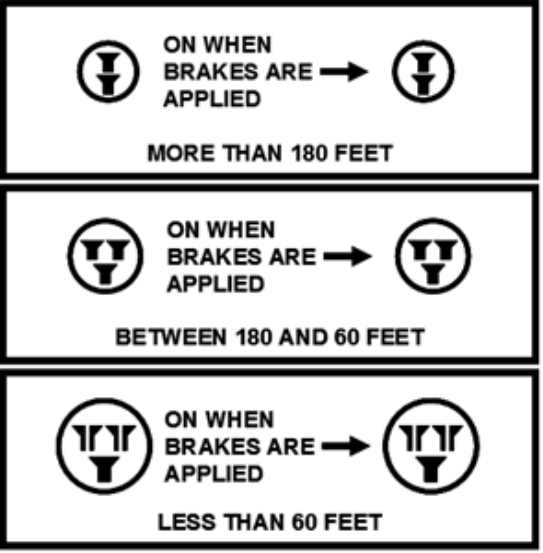

Figure 12.1. Rear BO Marker Lights. .......................................................................................... 127

AFMAN24-306 30 JULY 2020 13

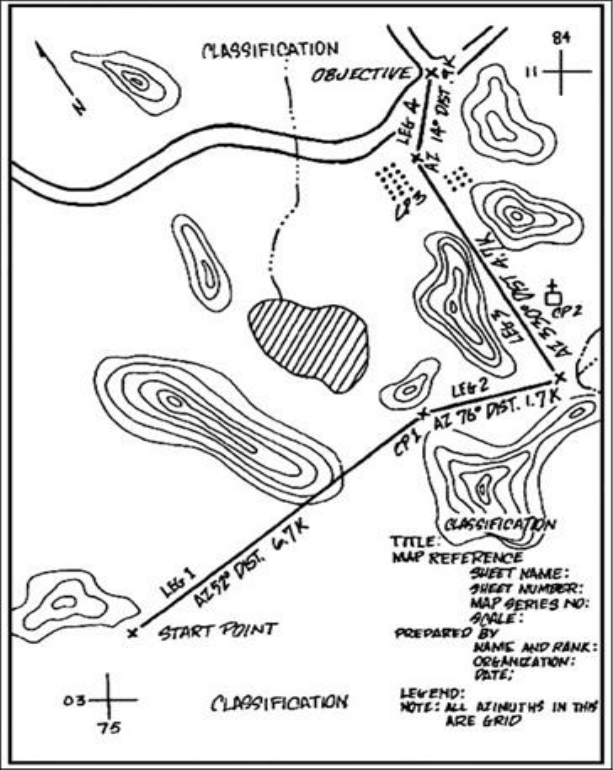

Chapter 13—LAND NAVIGATION 128

Section 13A—Navigation Considerations 128

13.1. Navigation Considerations. ...................................................................................... 128

Section 13B—Land Navigation Overview 128

13.2. Maps. ....................................................................................................................... 128

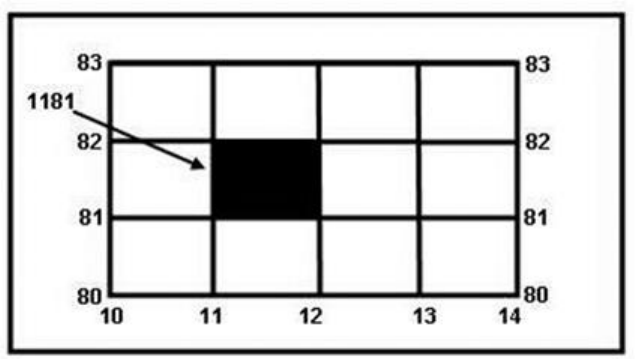

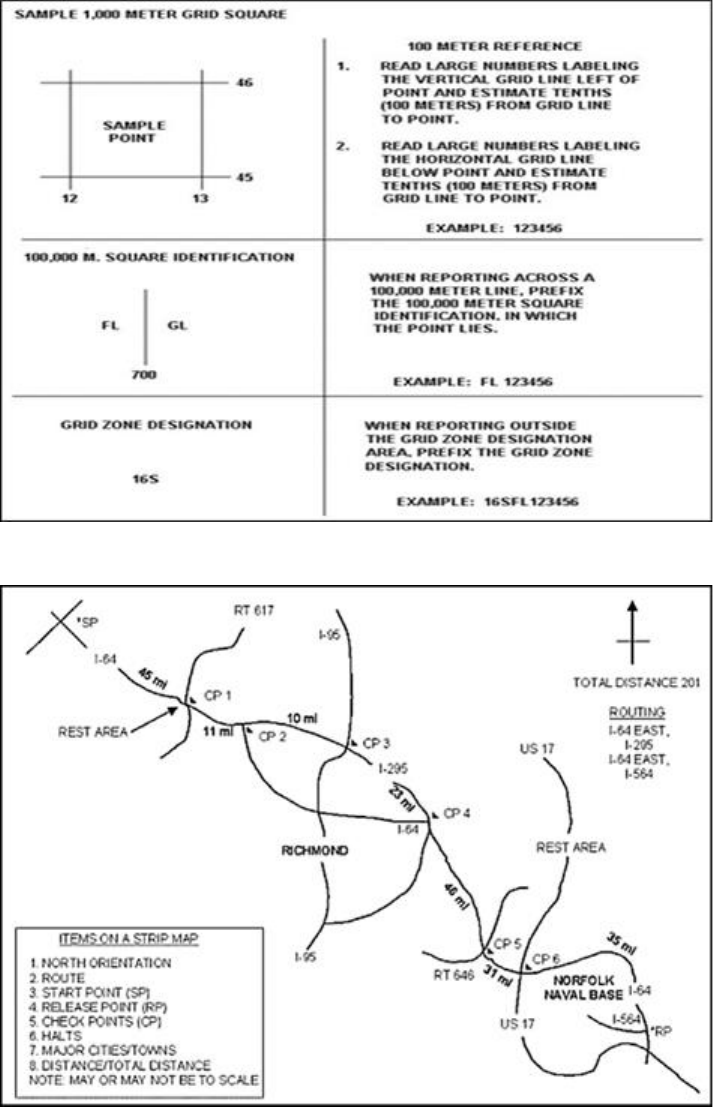

13.3. Military Grid Reference System. ............................................................................. 128

13.4. Grid Squares. ........................................................................................................... 128

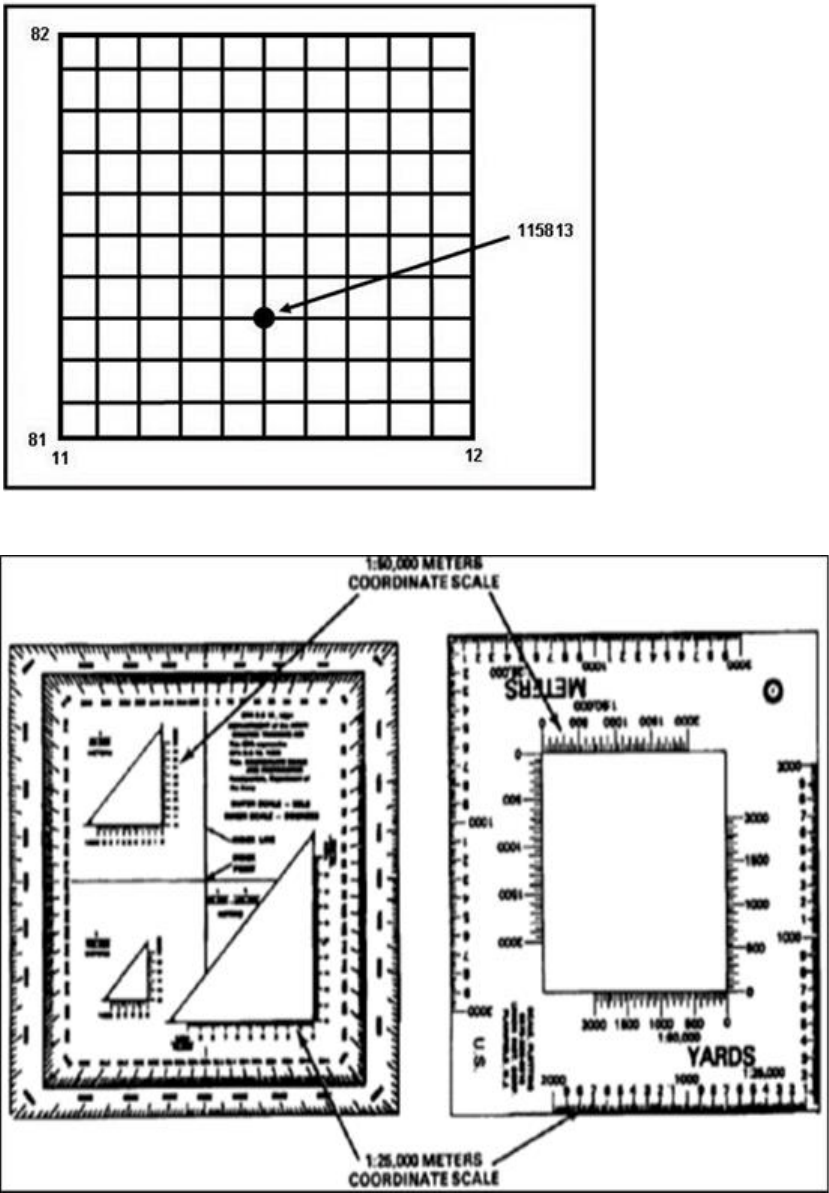

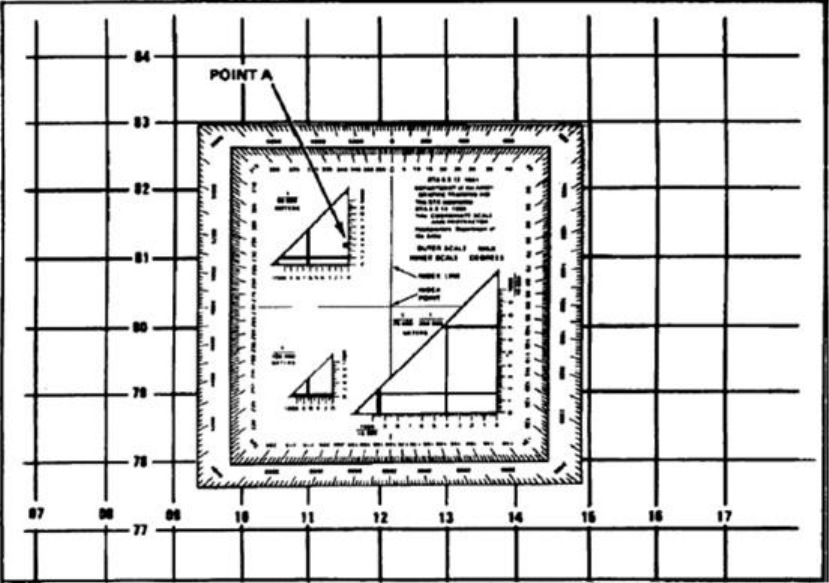

13.5. Determining Coordinates. ........................................................................................ 128

Figure 13.1. Grid Square. ............................................................................................................. 129

Figure 13.2. Point on a Grid Square. ............................................................................................ 130

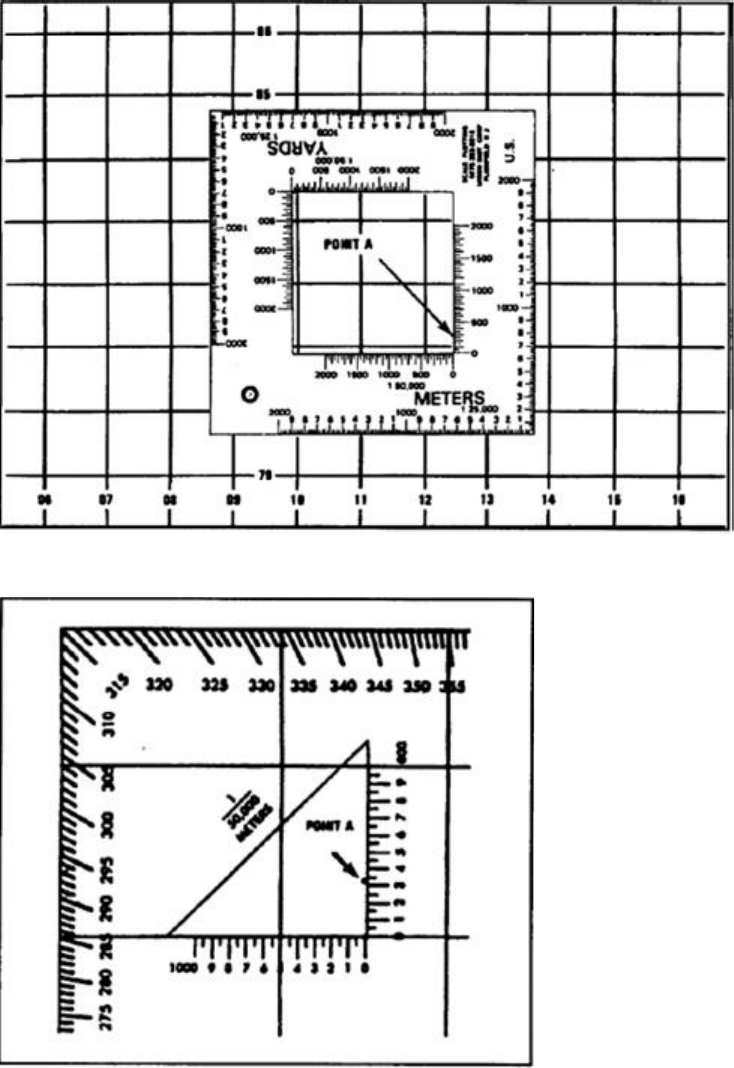

Figure 13.3. Coordinate Scales. ................................................................................................... 130

Figure 13.4. Determining Coordinates of a Point Using a Coordinate Scale. .............................. 131

Figure 13.5. Locating a Point on a Grid Square. .......................................................................... 132

Figure 13.6. Coordinate Scale. ..................................................................................................... 132

Figure 13.7. Grid Reference Box. ................................................................................................ 133

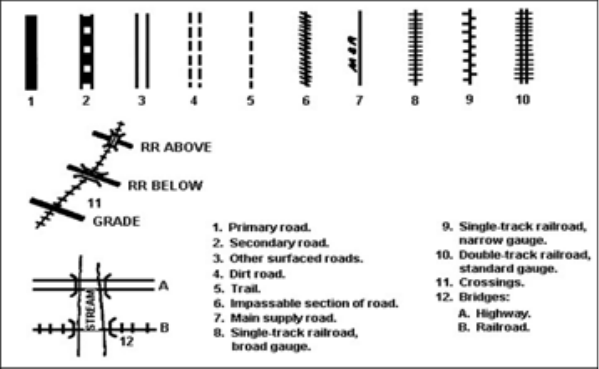

Figure 13.8. Strip Map. ................................................................................................................ 133

13.6. Estimating the Distance. .......................................................................................... 134

13.7. Unit Measurements. ................................................................................................. 134

13.8. Estimating the Time. ................................................................................................ 134

13.9. Recognizing Military Signs. .................................................................................... 134

Figure 13.9. Strip Map Symbols. ................................................................................................. 134

13.10. Using a Strip Map. ................................................................................................... 135

Section 13C—Prepare Before Movement 135

13.11. Movement Preparation. ............................................................................................ 135

Section 13D—Terrain Association Navigation 135

13.12. Terrain Association. ................................................................................................. 135

Figure 13.10. Primary Route. ......................................................................................................... 137

Section 13E—Electronic Navigation Equipment 137

13.13. Precision Lightweight Global Positioning System (GPS) Receiver (PLGR). ......... 137

14 AFMAN24-306 30 JULY 2020

13.14. Defense Advanced Global Positioning System (GPS) Receiver (DAGR). ............. 137

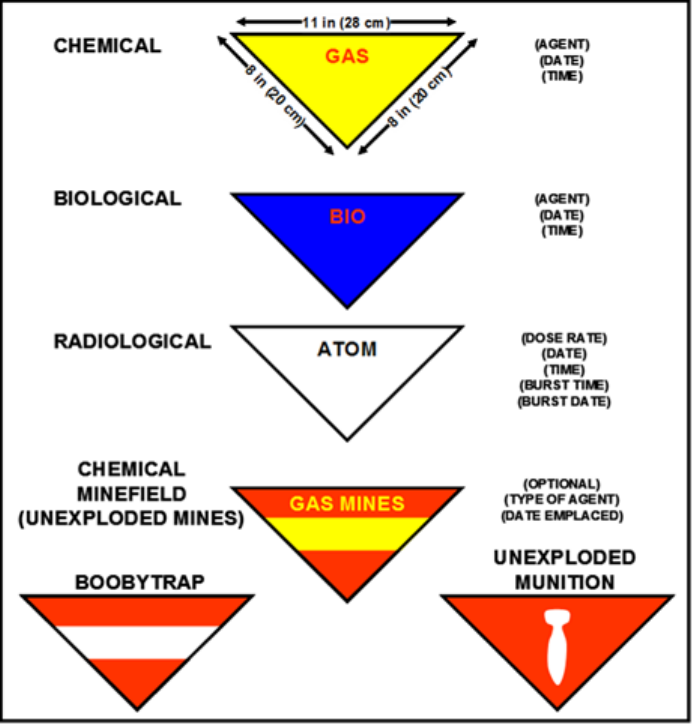

Chapter 14—CHEMICAL, BIOLOGICAL, RADIOLOGICAL, AND NUCLEAR (CBRN)

OPERATIONS 138

Section 14A—Operations in CBRN Environment 138

14.1. General Information. ................................................................................................ 138

Section 14B—Practices for Operating Vehicle in Contaminated Area 138

14.2. Operating a Vehicle in a Contaminated Area. ......................................................... 138

14.3. Vehicle Operation While Wearing Protective Mask. ............................................... 138

14.4. Marker Descriptions. ............................................................................................... 139

Figure 14.1. Standard CBRN and Unexploded Ordnance Hazard Markers. ................................ 139

14.5. Vehicle and Equipment Decontamination. .............................................................. 139

14.6. Pre/Post- Attack Preparation. ................................................................................... 141

Table 14.1. Mission Criticality Level Codes. ............................................................................. 143

Attachment 1—GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION 145

AFMAN24-306 30 JULY 2020 15

Chapter 1

ROLES AND RESPONSIBILITIES

Section 1A—Introduction

1.1. Introduction. Military and civilian operators of Air Force GMVs must meet specific

qualifications to be certified. (T-0). The term operator denotes a level of competence in the safe

operation as well as an understanding of the vehicle’s capabilities and limitations. This includes

an understanding of current sub-components such as technologically advanced communications,

navigation, intercom systems, on-board material handling cranes, self-recovery winches,

integrated night-vision devices, weapons support systems, onboard electronic diagnostic systems,

and load responsibility.

Section 1B—Roles and Responsibilities

1.2. USAF/A4LR - Headquarters USAF Logistics Readiness Division

1.2.1. Develops policy for effective operation and official use of GMVs.

1.2.2. Liaises between Department of Defense (DoD) and components on operation of

GMVs and official use considerations.

1.3. AFIMSC, NGB and AFRC

1.3.1. AFIMSC, NGB and AFRC will validate and manage enrollment for the Ground

Transportation NCOIC Course by selecting Technical Sergeant selects, Technical Sergeants,

and Master Sergeants with 18 or less years in service when filling seat allocations. (T-1).

NOTE: Ground Transportation personnel meeting the above criteria who recently returned to

the career field from a Developmental Special Duty or are currently serving in a one-deep

positions will be given priority during the selection process.

1.3.2. Identify personnel attending Training, Validation, and Operations Examiner Course.

1.3.3. Air Force Domicile to Duty (DTD) requests will be coordinated through AFIMSC,

NGB or AFRC, as appropriate, prior to submission to AF/A4LR. (T-1). AFIMSC, National

Guard Bureau and Air Force Reserve Command are not the action officer for DTD requests,

but will conduct a Subject Matter Expert (SME) technical assessment of the request and

provide a concur/non-concur recommendation to the decision authority.

1.3.4. Create, review and approve standardized vehicle Qualification Training Packages, as

applicable.

1.4. Installation Commanders and Directors (or equivalent). Ensures the official use of

GMVs and enforces GMV policy in favor of strict compliance with rules outlined in this manual,

AFI 24-301 and DoDM 4500.36, Acquisition, Management, and Use of DoD Non-Tactical

Vehicles to preclude improper use of appropriations. (T-0).

16 AFMAN24-306 30 JULY 2020

1.5. Logistics Readiness Squadron Commanders and Directors (or equivalent)

1.5.1. Administer the installation Vehicle Misuse Reporting and Investigation Program in

accordance with (IAW) AFI 24-301, Ground Transportation. (T-1).

1.5.2. Using the parameters in para 1.3.1, identify to AFIMSC/XZTE the members

attending the Ground Transportation NCOIC course.

1.6. Unit Commanders

1.6.1. Appoint Vehicle Control Officials IAW AFI 24-302, Vehicle Management.

1.6.2. Oversee unit’s GMV qualification program to include periodic medical review

requirements for civilian personnel who operate GMVs.

1.6.3. When notified by the Logistics Readiness Squadron (LRS) Commander, investigate

GMV misuse and respond to the LRS Commander’s assessment and identify actions taken to

prevent further occurrences (if appropriate) within 15 calendar days of notification. NOTE:

At AFR installations, if the commander is a Traditional Reservist, replies should be by the

next scheduled Unit Training Assembly.

1.6.4. Be familiar with GMV use restrictions and what constitutes official use.

1.6.5. Restrict use of all GMVs, including those rented or leased, for official purposes only,

i.e., in support of authorized DoD functions, activities, or operations only.

1.6.6. Notify the LRS/Operator Records and Licensing (OR&L) section of all suspension

and reinstatement actions IAW AFI 24-301, Ground Transportation. (T-1).

1.6.7. Ensure unit personnel are briefed annually on Air Force policy regarding official use,

accident reporting procedures, vehicle abuse, vehicle misuse, discrepancy reporting, proper

backing, use of spotters and use of DD Form 518, Accident Identification Card, SF 91, Motor

Vehicle Accident Report, and SF 94, Statement of Witness. (T-1). Briefings should be

documented and tracked by the Vehicle Control Officer or commander in a central location

(Vehicle Control binder, electronic database, individual training record, etc.).

1.6.8. Support the installation Accident and Abuse Program to include reimbursements IAW

AFI 24-302, Vehicle Management.

1.7. LRS - Ground Transportation

1.7.1. Serves as the functional experts on GMV Official Use determinations.

1.7.2. Ensures each unit that utilizes the Online Vehicle Interactive Management System

Dispatch Module (OLVIMS) has a base site code loaded into the module. If there is a

requirement to add a base and or site code to OLVIMS Dispatch Module, a request must be

submitted through AFIMSC, NGB or AFR, and then submitted to the Air Force Program

Executive Office ESC/HGGJV Program Management Office. (T-1).

1.7.3. National Guard Bureau and Air Force Reserve units operating their own LRS or

transportation functions will maintain separate OLVIMS Dispatch Module Site Codes to de-

conflict National Guard Bureau, Air Force Reserve, and Regular Air Force Duty Ground

Transportation manpower and license data collection. (T-1).

AFMAN24-306 30 JULY 2020 17

1.8. Vehicle Control Officials

1.8.1. Ensure unit personnel are briefed annually on Air Force policy regarding official use,

accident reporting procedures, vehicle abuse, vehicle misuse, discrepancy reporting, proper

backing, use of spotters and use of DD Form 518, Accident Identification Card, SF 91, Motor

Vehicle Accident Report, and SF 94, Motor Vehicle Accident Statement of Witness. (T-1).

Briefings will be documented and tracked by the unit Vehicle Control Official or commander

in a central location (Vehicle Control Official binder, electronic database, individuals

training record, etc.). (T-1).

1.8.2. Serve as the certifying official on the AF Form 171, Request for Driver Training and

Addition to U.S. Government Driver’s License. (T-1).

1.8.3. Support the installation Accident and Abuse Program to include reimbursements IAW

AFI 24-302, Vehicle Management.

18 AFMAN24-306 30 JULY 2020

Chapter 2

OFFICIAL USE OF GOVERNMENT MOTOR VEHICLES

Section 2A—Official Use Requirements

2.1. Official Use of GMVs. GMVs are closely controlled because of their easy accessibility,

high visibility and potential for misuse. DoDM 4500.36, implements federal law (e.g., 31 United

States Code (U.S.C) §1344 and 40 U.S.C §601-611) and prescribes the limited use of GMVs to

official governmental purposes. Unauthorized use of GMVs results in unneeded expenditure of

funds and creates public criticism. Commanders, operators of GMVs, and the base populace

must be familiar with GMV use restrictions and what constitutes official use of government

vehicles. (T-0).

2.1.1. Initial and Annual Training Requirement. Annually, the unit Vehicle Control

Official, or commanders with permanently assigned GMVs, will brief their personnel on Air

Force policy IAW para. 1.6.7 This training will be documented and tracked by the unit

Vehicle Control Official or commander in a central location (Vehicle Control Official binder,

electronic database, individuals training record, etc.). (T-1).

2.1.1.1. Operators of Air Force GMVs will operate GMVs for official use only and in

compliance with this manual, federal and state law, as wells as DoD and Air Force

guidance as they apply to the proper, safe, and efficient operation of Air Force GMVs.

(T-0). Unit members are required to contact their unit’s VCO for training prior to initial

operation of a GMV.

2.1.2. Restrict use of all GMVs, including those rented or leased, for official purposes only,

i.e., in support of authorized DoD functions, activities, or operations only. (T-0).

2.1.3. Transportation by a GMV shall not be provided when the justification is based

principally on reasons of rank, position, prestige or personal convenience. (T-0).

2.1.4. When questions arise about the official use of a GMV, they will be resolved in favor

of strict compliance with statutory provisions and AFI 24-301 and DODM 4500.36. (T-0).

Refer requests which appear to conflict with governing directives to the Ground

Transportation Noncommissioned Officer in Charge (NCOIC) for review.

Section 2B—General Use Responsibilities

2.2. General Use Responsibilities.

2.2.1. All personnel responsible for operating GMVs in any capacity and those developing

vehicle-related training plans should remain current with this manual and related installation

policy and or instructions.

2.2.2. Alcoholic beverages will not be consumed in GMVs. (T-0). Operators will not

consume alcohol eight hours prior to duty or prior to operating any GMVs. (T-0). Operators

are ultimately responsible for exercising good judgment by imposing additional time

constraints as needed.

AFMAN24-306 30 JULY 2020 19

2.2.3. Personal or government-issued hand-held wireless devices (e.g., phones or text

messaging equipment) or any other type of electronic devices will not be used while

operating a GMV. (T-0). Hands-free communication equipment (blue-tooth enabled

vehicles, speakerphones, single-bud earphones, mounted phones, etc.) may be used IAW

applicable state or local laws.

2.2.4. Tobacco or alcohol products will not be used in GMVs. (T-0).

2.2.5. Food will not be consumed while operating a GMV. (T-0).

2.3. Making Official Use Determinations. When guidance does not specifically fit a request

for transportation support, commanders must consider the following prior to approving the use of

a GMV: (T-0).

2.3.1. The purpose of the vehicle use must be essential to the successful completion of a

DoD function, activity, or operation. (T-0).

2.3.2. The purpose of the vehicle use must be consistent with the purpose for which the

GMV was acquired. (T-0).

2.3.3. If provided, GMV transportation used must be the most cost effective method of

satisfying the requirement, consistent with AFI 24-301. (T-0).

2.4. Priority of Transportation Services. When vehicle transportation is essential to the

performance of official business, the following methods shall be considered in the order shown

to the extent they are available and capable of meeting mission requirements: (T-0).

2.4.1. Scheduled DoD bus service.

2.4.2. DoD specially scheduled leased or owned bus service.

2.4.3. Van pools.

2.4.4. GMV centrally dispatched “taxicab” operation. (Example: Operator and vehicle

support requested from Ground Transportation).

2.4.5. GMV individually dispatched to licensed service member or civilian employee.

(Example: Unit assigned vehicle or U-Drive-It from Ground Transportation).

2.5. Vehicle Misuse Reporting. Report all suspected misuses to LRS-Ground Transportation

utilizing the AF Form 870, U.S. Government Motor Vehicle Suspected Misuse Report. Ground

Transportation conducts an initial technical assessment of the incident to determine if regulatory

official use guidance may have been violated. NOTE: AF/A4LR serves as the primary point-of-

contact for misuses or reckless vehicle operation allegations reported to General Services

Administration.

20 AFMAN24-306 30 JULY 2020

2.5.1. Ground Transportation collects the information and conducts a technical assessment

for review IAW AFI 24-301. Ground Transportation then forwards the AF Form 870, U.S.

Government Motor Vehicle Suspected Misuse Report to the LRS commander and then who

will forward the documentation onto the appropriate unit commander. Commanders have 15

calendar days to respond to the LRS commander's assessment and identify actions taken to

prevent further occurrences (if appropriate). Unit commander responses should address

requirements identified in paragraph 2.3 NOTE: At Air Force Reserve installations, if the

commander is a Traditional Reservist, replies will be by the next scheduled Unit Training

Assembly.

2.5.2. Ground Transportation maintains a log of reported misuse cases IAW AFI 24-301.

The misuse log with technical assessments and unit responses will be kept on file for three

years (RDS: T24-03R10.00).

2.6. Penalties for Misuse of DoD Motor Vehicles. The negligent or willful misuse of a GMV

may be cause for disciplinary action as described in DoDM 4500.36., Enclosure 5. (T-0). This

includes action against military members for violation of Article 92 of the Uniform Code of

Military Justice.

2.6.1. Misuse, acts or omissions resulting in misuse of GMVs (owned, rented, or leased)

may result in disciplinary action; refer to AFI 90-301, The Inspector General Complaint

Program, for guidance on fraud, waste and abuse.

Section 2C—Authorized Uses of GMVs for Temporary Duty Support

2.7. Temporary Duty. Transportation may be provided between lodgings and duty stations for

personnel on temporary duty when public or commercial resources are inadequate or

nonexistent. The temporary duty status of an individual does not necessarily justify the use of a

GMV or its use for personal convenience. Use of the vehicle will always be predicated on need,

distance involved, and other conditions that justify its use to further the DoD and Air Force

mission. (T-0). When an adequate DoD or commercial bus system is available or can be

provided, the use of any GMV or commercial rental car is prohibited.

Section 2D—Standard Authorized Uses of GMVs for Permanent Party Mission Support

2.8. Permanent Party. Official use by Regular Air Force personnel includes transportation to

or from Air Force scheduled appointments on- or off-base, e.g., Military Personnel Section

records check, dental appointments, commander’s calls (special consideration must be taken to

prevent transportation that circumvent official use rules for purposes of morale or personal

convenience), urinalysis testing and hospital outpatient appointments. (T-1). GMV travel is not

authorized for elective surgery, procedures or treatments where the member would otherwise not

be entitled to government travel. Use transportation priorities specified in paragraph 2.4

AFMAN24-306 30 JULY 2020 21

2.8.1. Permanent party personnel conducting official off-base duties are authorized to stop at

off-base eating establishments in the immediate vicinity or direct route of the off-base work

site. Stopping at (on- or off-base) private quarters for any reason or stopping for shopping or

personal convenience purposes is prohibited. The intent is to allow for those personnel

working away from their duty location, for extended periods, the opportunity to obtain meals

without incurring an additional time and fuel cost of returning to the installation. This is not

to be taken as authority to stop as a matter of personal convenience when in transit between

sites, whether on- or off-base.

2.8.2. Personnel conducting official off-base duties are authorized to respond to personal

emergencies that may arise while they are conducting off-base duties in a GMV. Personal

emergencies are defined as notification of a life threatening or serious injury to a dependent,

family member, or substantial damage to personal property, such as a home fire.

2.8.3. Commercial Terminal Transportation. Use of resources to support administrative

activities, for which sufficient public transportation or commercial services exist to fulfill the

need, detracts from direct mission support and should be avoided. Use of GMVs for travel to

transportation terminal are location and/or instance specific. Contact the servicing Ground

Transportation office and refer to AFI 24-301, and DODM 4500.36, Enclosure 5 for more

information.

2.8.3.1. National Capitol Region. Terminal transportation is not authorized in the

National Capital Region and Pentagon Area IAW DoD Administrative Instruction 109

unless necessary because of emergency situations, to meet security requirements or

unusual circumstances. Approval authority for services provided under this exemption is

Air Force District of Washington (AFDW)/A4. All requests must contain a detailed

explanation of why the exemption is required under one of the above noted clauses.

2.8.4. Mortuary Affairs. GMV support may be authorized IAW AFI 34-501, Mortuary

Affairs Program.

2.9. Event Participation.

2.9.1. Public Ceremonies. The use of GMVs may be authorized for military and civilian

personnel officially participating in public ceremonies, military field demonstrations, and

parades directly related to official activities. “Official participation” are activities similar to

and including: serving as a presiding officer, host, chaplain, master of ceremonies, guest

speaker or a proffer. Merely attending does not constitute “officially participating” even if

the public ceremony has been established as an alternate duty location.

2.9.2. General shuttle support from one official location to another official location may be

used as a mitigation measure IAW a vulnerability assessments IAW DoDI O-2000.16V1,

DoD Antiterrorism Program Implementation.

2.9.3. The use of GMVs is authorized to transport immediate family members (i.e., spouse,

children, and parents) of the sponsor in situations involving a sponsor’s death. The LRS

Commander is the approval authority. (T-0).

22 AFMAN24-306 30 JULY 2020

Section 2E—Special Authorized Uses of GMVs for Permanent Party Mission Support

2.10. Mission-Specific Authorizations. Certain mission-specific allowances are authorized if

incident to the performance of duty. Units will submit requests and justification to Ground

Transportation for SME review/recommendation. (T-1). The consolidated package with the

LRS Commander’s recommendations will be coordinated thru the Office of the Staff Judge

Advocate and then onto the Installation Commander for review and final determination. (T-1).

Approval determinations will be provided to each requesting unit commander. (T-1). Mission-

specific authorizations will not be extended to activities other than those listed in this section.

2.10.1. Emergency Response Forces. Travel to on base eating establishments and base

gymnasium by Emergency Response Forces when on alert status is approved. This approval

includes the use of Military Dining Facilities and NAF/AAFES/ Defense Commissary

Agency operated eating establishments to include commissary and shoppette. The intent is to

allow personnel to remain on duty and maintain the ability for immediate response while

securing meals for health and sustenance. Leadership within units authorized to travel to on-

base eating establishment must ensure personnel do not abuse or cause negative public

perception by frequenting establishments for reasons other than obtaining meals. (T-1).

Personnel are prohibited from using GMVs for travel to and from their private quarters under

this provision.

2.10.2. Bulk Meals/Flight Kitchens. Unit commanders may approve use of GMVs for the

purposes of securing carry-out meals in bulk from on-base military dining facilities or flight

kitchens. Examples include: Aircrew, Passenger Terminal, and Mobility and/or Contingency

Support. Do not grant any of the above authorities for the personal convenience of personnel.

Bulk Meals/Flight Kitchen support will be approve in accordance with the above mission

specific authorization guidance. (T-1).

2.10.3. Unless specifically authorized in another section of this instruction, Air Force GMVs

will not be used to transport personnel or equipment to or from base housing areas or other

private quarters located either on or off the installation. (T-0).

2.10.4. Mission-specific authorizations will not be extended to activities other than those

listed in paragraph 2.10.1 (T-0).

2.11. MAJCOM, Numbered Air Force, and Installation Commanders. When a permanently

assigned vehicle is authorized, Installation, Numbered Air Force, and MAJCOM commanders

may use that GMV for on-base travel to locations and tasks related to personal health and

sustenance (except member’s residence). This authorization accommodates the commander's

responsibility to ensure an immediate response capability and to facilitate travel to meet official

responsibilities. Permanent party official use rules (paragraph 2.8) apply for off-base travel and

stops. All other official use constraints as described in this chapter, including the provisions on

dependent and family member travel, apply.

2.11.1. This authorization shall not be interpreted as authority to use the GMV for stops at

their residence or other domicile-to-duty transportation. (T-0).

AFMAN24-306 30 JULY 2020 23

2.12. Operations Group Commanders (OG/CCs). When a telecommunications-equipped,

permanently assigned GMV is authorized, OG/CCs may drive that GMV to on-base eating

establishments (Military Dining Facilities and Non-appropriated Funds/AAFES/ Defense

Commissary Agency operated eating establishments to include commissary and shoppette) while

performing their duties in connection with official business. The intent of the policy is to allow

OG/CCs to use the assigned GMV for these activities while maintaining access to mounted

telecommunications equipment. This shall not to be interpreted as authority to use the GMV for

stops at their residence or other domicile-to-duty transportation. (T-0).

2.13. Domicile to Duty (DTD). Transport of individuals in GMVs from their domicile to place

of employment or home-to-work is not transportation for official purposes, except as specifically

identified or approved in accordance with DoDM 4500.36.

2.13.1. Air Force DTD requests will be coordinated through AFIMSC, National Guard

Bureau or Air Force Reserve Command for technical assessment and recommendation prior

to submission to AF/A4L. (T-1)

Section 2F—Dependent and Pet or Service Animal Transportation Support

2.14. General Dependent Transportation Support. Transportation of family members is the

responsibility of the sponsor. Spouses are not considered representatives of the United States,

DoD, or Air Force, except when traveling on an approved invitation travel authorization (see

paragraph 2.15).

2.14.1. A military dependent may accompany their military or civilian employee sponsor

when the GMV is being used to accomplish official business, the military or civilian sponsor

will participate in an official capacity for the function and there is space available.

2.14.1.1. On a space available basis, accompanying the military member or civilian

personnel in the GMV to meet the Air Force member’s dependent at the event for which

the use of the vehicle has already been authorized to accomplish the official business.

Transportation will be provided at no additional cost to the government. (T-0). The

vehicle must be no larger than required for the official business. (T-0). Such

transportation will be included in annual accounting and reporting of domicile-to-duty

transportation for the Air Force member spouse.

2.14.1.2. On a space available basis, dependents may use publicized, regularly scheduled

shuttle buses or mass transportation services. Space available basis may not be utilized to

circumvent travel to support events such as: breakfasts, luncheons, dinners, icebreakers,

socials, holiday parties, fini-flights and homecomings etc. The events listed in this

paragraph are examples and do not constitute an all-inclusive list.

2.14.1.3. Dependents of personnel who are authorized by DoD to receive domicile-to-

duty transportation may proceed independently to or from an official function in a GMV

when the dependent's presence at the function is in the best interest of the government.

2.15. Invitational Travel Authorization Special Dependent Transportation Support.

2.15.1. Spouses on official ITA orders are authorized ground transportation in direct support

of the invitation only, e.g., travel to and from transportation terminal, billets, and event

site(s). Contact LRS-Ground Transportation for more information.

24 AFMAN24-306 30 JULY 2020

2.16. Pet and Service Animal Transportation Support.

2.16.1. The use of GMVs for the transportation of family pets is authorized for Permanent

Change of Station (PCS) (i.e., only PCS moves at austere locations where public or private

transportation is not available), execution of Installation Emergency Management Plan, Non-

Combatant Evacuation Operation, SAFEHAVEN, etc. The pet must always be under the

control of the owner, either leashed or caged, in order to ensure the safety of the operator and

passengers. (T-1). Owners will be held responsible for the behavior of their pets and any

costs associated to damage caused by the pet. (T-1).

2.16.2. Service animals are authorized to accompany the individual requiring support in

GMVs. The service animal must always be under the control of the owner, either leashed,

harnessed or caged, to ensure the safety of the operator and passengers. (T-1). Owners will

be held responsible for the behavior of their service animal and any cost associated to

damage caused by the animal. (T-1). Failure to do so will result in the immediate

termination of support. (T-1).

Section 2G—DoD Agency Transportation Support (non-inclusive)

2.17. Civil Air Patrol Support. Civil Air Patrol is authorized Air Force transportation support

when performing Air Force assigned missions as a volunteer civilian auxiliary of the Air Force

IAW AFI 10-2701, Organization and Function of the Civil Air Patrol. Air Force Installation

Commanders may provide government transportation and equipment to Civil Air Patrol units on

a temporary basis. When providing transportation or equipment to Civil Air Patrol units, the

Installation Commander must also provide a sufficient number of qualified personnel to operate

the vehicles or equipment. (T-1). If requested by Civil Air Patrol, the Air Force may provide

licensed and qualified operators for Civil Air Patrol ground transportation support. Civil Air

Patrol members are not authorized to drive GMVs. (T-1). Refer to AFI 10-2701 for questions

regarding authorized Civil Air Patrol support.

Section 2H—General Unauthorized uses of Air Force Vehicles (Note: This is not an exclusive

list)

2.18. Miscellaneous Event Support. Breakfasts, luncheons, dinners, icebreakers, socials,

holiday parties, fini-flights, picnics, wing/unit booster clubs, other private organizations, fridge

funds, fundraisers or activities resulting in fundraising, TOP 3 or 4, company grade officers or

enlisted councils, Air Force Balls and similar events, shopping, sightseeing, clubs or functions

on- or off-base are not official. As such, they are not authorized for GMV support. The events

listed in this paragraph are examples and do not constitute an all-inclusive list.

2.19. Personal or Social Engagements. Members and their dependents will not use GMV

transportation for personal social engagements or personal business. (T-0). Members and their

dependents may use publicized, regularly scheduled transportation services on a space-available

basis. Larger vehicles will not be provided to accommodate space-available passengers. (T-0).

2.20. Household Goods Movement. Do not use GMVs for personal or government-directed

household goods moves. (T-0).

AFMAN24-306 30 JULY 2020 25

2.20.1. Members are not authorized GMV support for moves related to dormitory renovation

or commander-directed relocations. Members facing such moves are authorized to receive

all appropriate personal property shipping entitlements. Refer requests for household goods

moves to LRS-Personal Property Element. (T-0).

2.21. GMV Parking Locations. Unless incident to the performance of official duty, do not use

or park GMVs at commissaries, base exchanges (including concessions), bowling centers, officer

and enlisted clubs, gymnasiums or any Non-appropriated Fund activity (i.e., golf courses, rod &

gun clubs) unless authorized as set forth in Chapter 2.

2.22. Permissive TDY Status. Members traveling in Permissive Temporary Duty status are not

authorized dedicated appropriated funded GMV transportation support. Permissive Temporary

Duty status is authorized at no cost to the government. Members in this duty status may use

publicized, regularly scheduled transportation services (e.g., shuttle buses, airport transportation

service) on a space-available basis. Do not provide a larger vehicle to accommodate space-

available passengers. (T-0).

26 AFMAN24-306 30 JULY 2020

Chapter 3

LICENSING AND TRAINING

Section 3A—Operator Records and Licensing (OR&L) General Information and

Administration

3.1. Policy. Air Force GMVs shall only be operated by military personnel, civilian employees,

approved civilian contractors and Non-appropriated Fund employees who meet all criteria of this

manual and criteria found in AFI 24-301. (T-0). All personnel operating a GMV will be

licensed IAW AFI 24-301 and this manual. Ground Transportation Leadership is the installation

authentication officials.

3.1.1. United States Air Force Academy cadets are authorized to operate Air Force vehicles.

3.1.2. Reserve Officer Training Candidate (ROTC) cadets under an enlistment contract and

issued a military identification card are considered active duty military and are authorized to

operate Air Force GMVs IAW AFI 24-301, Ground Transportation.

3.1.3. Military or government civilians assigned to, or detailed to provide support to, Civil

Air Patrol may operate GMVs.

3.1.4. Junior Reserve Officer Training Candidate (JROTC) instructors are employees of their

local school districts and not the Air Force. Therefore, they are not authorized to operate

GMVs. (T-1).

3.1.5. Foreign military personnel may operate Air Force vehicles when on official orders

performing temporary duty or deployed to an Air Force installation. The individual must

present an international license and/or applicable military license issued by their military

service. (T-0). Before operating any Air Force vehicle, the vehicle operator must

demonstrate proficiency and be briefed by the sponsoring unit on official use policies,

accident reporting, vehicle abuse and operator care responsibilities. (T-1). Additionally,

members must receive Local Conditions Course IAW AFI 91-207, The U.S. Air Force

Traffic Safety Program, if in Temporary Duty status more than 30 days. (T-1). Permanently

assigned foreign military personnel may operate Air Force vehicles provided such support is

approved by the Installation Commander, often by Memorandum of Understanding or

Memorandum of Agreement and are in compliance with other licensing requirements in this

chapter. (T-1).

3.2. OR&L Office. This office is responsible for licensing and maintaining motor vehicle

operator records for those military and civilian personnel authorized to operate Air Force owned,

rented or leased motor vehicles requiring additional training and certification.

3.3. Driver Records. The OR&L staff maintains active records (AF Form 2296, Operator

Qualification Record) for all authorized operators requiring additional licensing assigned to the

installation. Operator records will be retained in the Online Vehicle Interactive Management

System (OLVIMS) Dispatch Module. (T-1).

AFMAN24-306 30 JULY 2020 27

3.3.1. When personnel transfer from one unit or installation to another, their driver record

must be updated by the gaining unit’s servicing Operator Records and Licensing (OR&L)

office prior to operating a GMV at their new unit/installation. (T-1).

3.3.2. Vehicle Control Officials coordinate with assigned personnel and the OR&L office for

renewal and/or out-processing of personnel with expired licenses, as appropriate.

3.4. Military and Civilian Employee Licensing. Operation of Air Force GMVs requires

possession of a valid Department of Defense issued Common Access Card and valid state motor

vehicle operator’s license.

3.4.1. Operation of non-tactical Air Force GMVs where the gross vehicle weight rating

(GVWR) is less than 26,000 pounds, designed to transport 8 passengers or less and does not

have a standardized AFQTP, requires a valid state motor vehicle operator’s license and a

valid DoD issued Common Access Card. No further licensing is required.

3.4.2. Operation of all other Air Force GMVs (to include tactical vehicles and material

handling equipment) requires additional training, certification, and licensing.

3.4.3. Completion of additional training and certification will be documented on the AF

Form 2293. (T-1). Operation of GMVs is limited to those vehicles identified on the AF

Form 2293 and those that can be operated with only a state motor vehicle operator’s license.

3.4.4. International drivers’ licenses cannot be used in lieu of the AF Form 2293, U.S. Air

Force Motor Vehicle Operator Identification Card. The Air Force will honor validated sister

service licenses such as the Optional Form (OF) 346, U.S. Government Motor Vehicle

Operator’s Identification Card. (T-1).

3.4.5. Special Licensing considerations. Due to mission and type, specific vehicles have

been given a special licensing consideration. Vehicle training and certifications for those

vehicles designated in paragraph 3.4.5.1 will be documented in personnel records. (T-0).

The owning unit must ensure proper training to include lesson plan development/use and/or

special certifications are maintained as required for the applicable vehicle(s). (T-1).

3.4.5.1. Water vessels do not require licensing on the AF Form 2293.

3.4.6. Remote processing. OR&L may have remote processing available for licensing

actions. VCOs should contact the servicing OR&L office for more information.

3.4.7. When operation of a GMV requiring an AF Form 2293 is needed, the unit VCO

checks the individual’s state motor vehicle operator’s license for medical or physical

restrictions and notes them on the AF Form 171, if applicable. Any restrictions are annotated

on the AF Form 2296 and printed on the AF Form 2293. Unit commanders are the

authorized signatory for AF Form 171 for units without a VCO program. This authority may

be delegated by identifying an authorized alternate in writing to the OR&L office. This

designation will be locally administered. (T-1).

28 AFMAN24-306 30 JULY 2020

3.4.7.1. Personnel who receive training and a signed AF Form 171, Request for Driver’s

Training and Addition to U.S. Government Driver’s License, on GMVs while deployed

or TDY are authorized to have their AF Form 2293 and AF Form 2296 annotated to

reflect training for that vehicle(s). Current unit commander’s or VCO’s signature on the

AF Form 171 will be sufficient certification. (T-1). Additional certification by the TVO

section IAW this manual and AFI 24-301 is still required on applicable GMVs prior to

licensing.

3.4.7.1.1. The member presents the AF Form 171 to the OR&L staff who establishes